Best design complete 8t/h pig and 8t/h dairy cow feed pellet production factory project in China

-

Country:China

-

Application: dairy cow and pig feed mill

-

Output:16 Tons per hour

1. Construction scale

The annual output of high-quality compound feed is 40,000 tons (16t/h), and the product plan is 20,000 tons (8t/h) for pig feed and 20,000 tons (8t/h) for dairy cow feed.

2.Cost of pig cattle animal feed manufacturing plant

The total investment of the project is 12 million yuan. Among them: fixed asset investment is 9 million yuan, working capital is 3 million yuan, all funds are raised by the enterprise itself.

3.Equipment needed to start a 8t/h pig feed and 8t/h dairy cow feed production plant

| Equipment name | Specification model | Quantity (unit) |

| Raw material receiving and cleaning stage | ||

| Level device | BC15-K34-AZ3X | 2 |

| Scraper conveyor | TGSU25 | 1 |

| Bucket elevator | TDTG50/23 | 1 |

| Cylinder preliminary cleaning screen | SCY63 | 1 |

| Permanent magnet cylinder | TXCT25 | 1 |

| Rotary distributor | TFPX.12 | 1 |

| Feed crushing section | ||

| Leveler | / | 8 |

| Buffer bucket | / | 1 |

| Animal feed hammer milling grinder machine for cattle and pig | SESP112*38C | 1 |

| screw conveyor | TLSS25 | 1 |

| Bucket elevator | TDTG50/23 | 1 |

| Rotary distributor | TFPX.12 | 1 |

| Pulse dust collector | TBLMa21 | 1 |

| Matching fan | 4-72No4.5A | 1 |

| Batching and mixing section | ||

| Ingredients warehouse | / | 18 |

| Leveler | / | 40 |

| Screw feeder | TWLL28 | 4 |

| Batching scale | PCS | 2 |

| Add bucket manually | / | 1 |

| Double shaft high efficiency cattle pig feed mixer | SSHJ4 | 1 |

| Buffer bucket | / | 1 |

| Scraper conveyor | TGSU25 | 2 |

| Bucket elevator | TDTG50/28 | 1 |

| Rotary distributor | TFPX.4 | 1 |

| Fan | 4.72No4.5A | 1 |

| Pulse dust collector | TBLMa21 | 1 |

| Pelleting section | ||

| To be granulated bin | / | 1 |

| Level machine | / | 8 |

| Closed air feeder | / | 1 |

| Ring die cattle pig feed pelletizer machine | SZLH420 | 1 |

| Counter flow pellet cooler | SKLN6 | 1 |

| Crumbler machine | SSLG20×170+3 | 1 |

| Bucket elevator | TDTG36/28 | 1 |

| Cyclone grading screen | SFJH125×2d | / |

| Buffer bucket | / | 1 |

| Rotary distributor | TFPX.4 | 1 |

| Pulse dust collector | TBLMa46 | 1 |

| Fan | 4-72No5.0A | 1 |

| Packing section | ||

| Finished product warehouse | / | 1 |

| Leveler | / | 8 |

| Buffer bucket | / | 1 |

| Pellet packaging scale | / | 1 |

| Seam combined conveyor | / | 1 |

There is no standardized feed production plant in the client's local area, which cannot meet the requirements of modern aquaculture development, and there is a potential gap in feed supply. The client judged the situation, and after more than a year of investigation on the feed processing industry, he built a commercial animal feed making plant for pig and dairy cattle feed production in the northwestern region of China, which is rich in dairy farming resources, to develop the feed industry.

The process technology used in this 8t/h pig and 8t/h dairy cow feed production factory project is relatively mature. In the entire pig production process, the equipment selected for this animal livestock feed processing plant project is carried out in a sealed state from feeding, crushing, batching mixing, cooling, and granulation. Pulse bag dust collectors are installed at the dust points, and exhaust gas can be discharged up to the standard. Therefore, this dairy cow pig animal feed manufacturing project meets the requirements of cleaning production in terms of energy saving, consumption reduction, and pollution reduction.

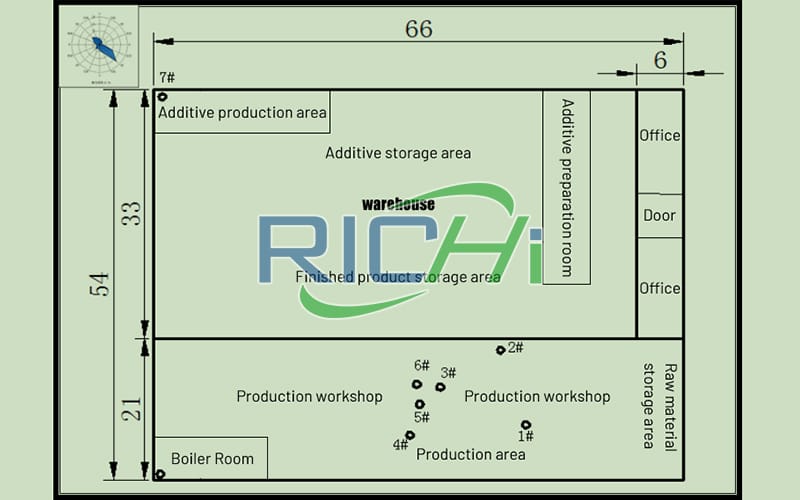

4. Layout of animal livestock feed processing plant for 8t/h pig feed and 8t/h dairy cow feed production

The totally 16 tons per hour animal pig dairy cow compound feed mill factory project covers an area of about 20,000m2. In order to make use of the original plant and make the plant transportation convenient, the production process flow is smooth, short and reasonable, it is planned to use the original main plant as the raw material and finished product warehouse, and build the main production workshop on the east side of the original main plant and boiler room on the south side of the original main plant.

The living area still uses the original office on the north side of the factory. The production and living areas of the factory are clearly defined, and the greening and beautification of the factory environment has been strengthened. The greening is mainly based on the greening of the roads on both sides of the dairy cow and pig feed factory. The greening of the open space around the workshop is supplemented by the green area of 5000 square meters and the greening rate is 25%.

SZLH-508 Feed Pellet Machine

SZLH-508 Feed Pellet Machine  SKLN Series Counterflow Cooler

SKLN Series Counterflow Cooler  SLHJ Feed Mixer Machine

SLHJ Feed Mixer Machine  SFSP Animal Feed Crusher

SFSP Animal Feed Crusher