Complete set pig animal feed pellet production line with factory price for sale

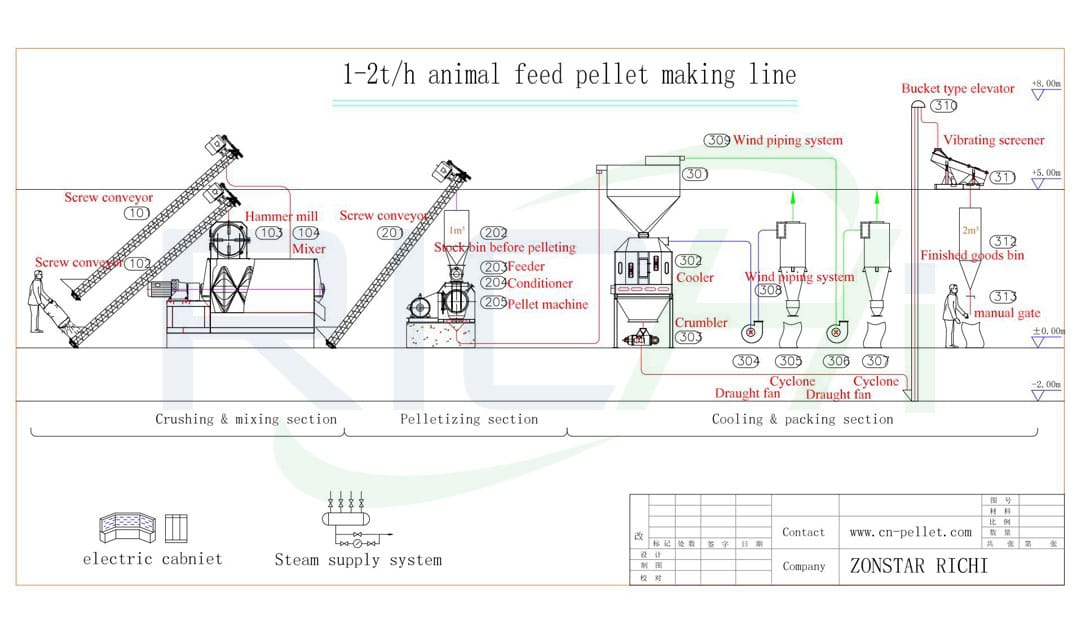

The complete set pig animal feed pellet production line is the feed processing equipment used by many relatively large pig feed mills. Richi Machinery develops equipment plans based on the actual situation of the customer, which not only meets the customer's pig feed production needs, but also starts from the customer's actual situation. Provide customers with economical and practical feed equipment. Today, we are going to talk about the 1 ton per hour pig feed pellet processing equipment production line.

Richi Machinery produces a 1 ton pig feed pellet unit per hour, which uses an integrated pig feed mixer to pulverize the mixed material and conveys it to the 1t/h pig feed pellet mill machine by a screw conveyor, which is energy-efficient, efficient and durable.

1. Application: It is suitable for rural pig farms, small breeding plants and small sized pig feed mill. It can produce pig pellets, pig premix feed and other products.

2. Applicable raw materials: raw grains, soybeans, soybean meal, corn, fish meal, amino acids, miscellaneous meal, additives.

3. Equipment characteristics

(1) The 1 ton pig feed line integrates the functions of crushing, mixing, conveying, and pelleting, with advanced design, simple structure, wide applicability, small footprint and low noise.

(2) Powder feed and grass meal can be pelletized without (or a little) liquid addition. Therefore, the moisture content of pellet feed is basically the moisture content of the material before pelleting, which is more conducive to storage.

(3) The pellets made by 1 ton per hour pig feed pellet making plant have high hardness, smooth surface and sufficient internal maturation, which can improve the digestion and absorption of nutrients, and can kill common pathogenic microorganisms and parasites. It is suitable for feeding rabbits, fish, duck and laboratory animals can obtain higher economic benefits than mixed powdered feed.

(4) This model is equipped with a variety of aperture molds from 2.5mm to 10mm, which is suitable for granulating different materials.

(5) Adapt to different materials to ensure the suppression effect. Compression molding of wood chips and corn stalks requires a lot of pressure. In similar pig feed pelletizing equipment, the roller part is the central part of the entire pig feed pellet equipment, and the use of high-quality alloy steel improves the service life of the roller.

Richi Machinery supplies pig feed pellet unit, pig feed pellet processing machine, large-scale feed equipment, etc.RICHI is a large animal feed mill manufacturer from China devoting in feed processing equipment , integrating the design, manufacturing, installation, mainly produce all sorts of feed pellet machines, pig feed hammer mill crushing machine, pig feed mixing machine, conveying machine, pig pellet cooling machine,etc and the complete animal feed pellet production line machinery. About more pig feed processing machines details, please Email: enquiry@richi-machine.com, Whatsapp/Cel: +86 185 7410 3366.

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.