How to choose the processing parameters of the 300,000 laying hens farm?

The processing of laying hen feed pellets by the chicken feed pellet plant is very different from the ingredients of the laying hen farm itself.

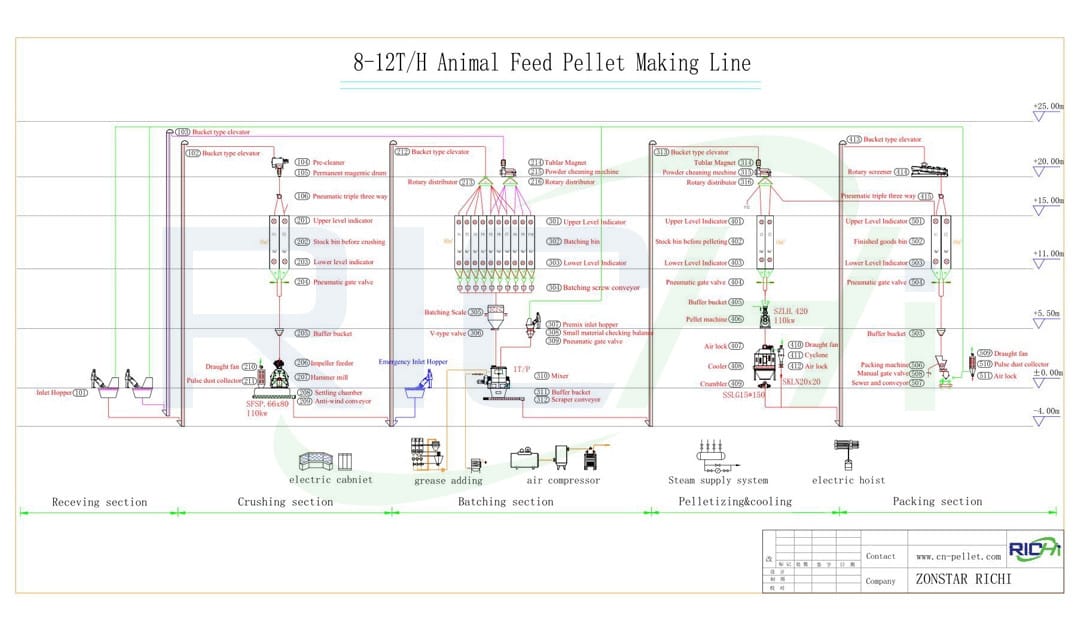

1.Flow Diagram of Laying Hen Feed Pellet Processing Plant:

RM Receiving & Precleaning System—Grinding System—Dosing & Mixing System—Pelleting System—Bagging System—Auxiliary System

At the ingredient stage of the laying hen feed factory,the batching system is designed according to different feed formula, is accurate weighing process of different raw materials by using specific device. The mixing system is mixing various materials under the action of external force, after various materials are metered. It is an operation that makes the raw materials distribute evenly.

This process need use a set of batching scale, bins and the manual adding system with checking scale. After the dosing and weighing process are finished, the raw materials enter the mixer for mixing, and finally the raw materials are output by chain conveyor and bucket elevator.

2. Self-proportioning process of layer farm

The production process of the farmer's own ingredients for laying hens generally includes crushing and mixing.

(1) Raw material crushing stage

Crushing can increase the contact area of feed and digestive enzymes, which is conducive to the digestion and absorption of nutrients, but the crushing size is too coarse and too fine. Many raw materials such as corn and soybean meal (flakes) need to be crushed, and the grain size of the diet should be controlled according to different feeding stages.

The purpose of chicken feed mixing is to ensure that each component can exist uniformly in different parts. The coefficient of variation of the mixing uniformity of the compound feed mixer is required to be less than 7%. The equipment is fixed, and the factors affecting the mixing effect mainly include mixing time, fullness factor, feeding procedure, etc.

The equipment needed at this stage is:farm corn hammer mill machine

(2) Raw material mixing stage

The mixing time should be suitable. Different mixing machines and methods have different mixing times. The optimal mixing time for batching equipment in specialized feed factories is generally within 2 minutes, while the mixing equipment purchased by farmers is generally 5-10 minutes. Wait. Because in the process of material mixing, the mixing effect quickly reaches the optimal mixing uniform state with the extension of the mixing time. However, when the materials have been fully mixed, if the mixing time is extended, the mixing uniformity will decrease instead. In short, the mixing time is too short to achieve full mixing, and too long will cause separation and also affect the mixing quality. Richi Feed Technology can occasionally measure the mixing uniformity for customers to determine the best mixing time for customers.

In the order of feeding, generally 80% of the components with large proportions are first input into the mixer, then the materials with small proportions are input, and then the remaining 20% of the large components are input, so that the remaining large The components are covered on the micro components (premix), which can prevent the micro components from clumping into the blind corner or bottom of the mixer and other difficult to mix, and can avoid the flying loss of the micro components. If the mixer is equipped with a spray grease device, the liquid component should be added after mixing the powder for a period of time and mixed with the powder.

Filling coefficient refers to the ratio of the volume of the material loaded into the mixer and the volume of the mixer, its size affects the accuracy and speed of the chicken feed mixer.

The equipment needed at this stage are:animal feed mixer machine,rotary distributor,liquid adding machine

Whether it is a feed factory or a farm, although the process is different, the chicken feed formula is similar. A common feed formula for laying hens is recommended:

Soybean meal 28%

Cotton seed meal 26.5%

rape-seed cake 8%

Maize protein meal 4%

DDGS(distillers dried grains with soluble) 5%

Corn germ meal 2%

Stone powder 20%

Stone powder 20%

Calcium bicarbonate 4%

Premix 2.5%

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.