How to get more benefits in the late laying period of laying hens?

Under the influence of African swine fever and other factors, the good egg market and high egg price in the second half of 2019 is a good opportunity for laying hens to make money. Under such a good market, how to improve the egg production rate and egg quality has become a key factor to improve economic efficiency.

As we all know, the higher the peak value of laying hens during the laying period, the longer the peak period, the greater the profit of the farmers. However, in the practice of breeding, with the continuous increase of age, especially after the peak period, the production performance of the chickens gradually decreases, the egg shape increases accordingly, the strength of the egg shell decreases, the egg shell gradually thins, and the damage rate gradually increases. Thin-shelled eggs, sand-skinned eggs, and malformed eggs increase proportionately, and the egg production rate gradually decreases. Elimination of hens has a low weight and a high mortality rate. Elimination of hens at an unaffordable price has markedly reduced the economic benefits.

1. How to make the laying hens get more benefits in the late stage?

With the increase of the age of laying hens, especially after 36 weeks of age, the quality of eggshells is declining. After 55 weeks of age, the proportion of thin-shelled eggs, sand-skinned eggs, and malformed eggs increases. In the late stage of laying, the hens are aging, and the deterioration of egg quality is inevitable, causing great problems to many large-scale farms and causing huge economic losses.

Richi's suggestion: In the feed formulation, the 5% post-laying premix is used. According to the nutritional requirements of laying hens after 400 days, the problem of egg quality is improved from feed nutrition. Effectively solve the problems of rapid drop in egg production rate in the late period of laying hens, shortening of egg production cycle, and deterioration of egg quality, effectively improve egg quality and greatly reduce feeding costs.

Recommended chicken formula: corn 60.5%, bran 7%, soybean meal 19%, stone powder 8.5%, premix 5%. This type of formulation has been tested many times, but customers need to use a high-quality 5% premix. If a good 5% premix is used, after 35 weeks, not only will the egg production rate increase, the peak egg production period will be extended, and the decline in egg production rate will also be gentle.

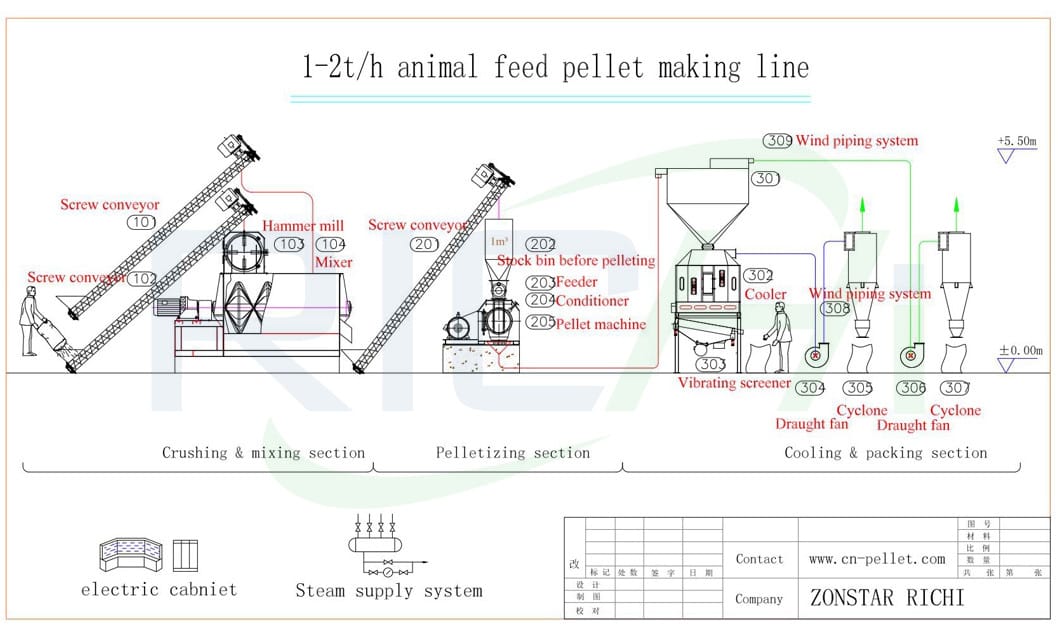

2. Flow of layer pellet feed processing plant

(1)Raw material crushing: crushing corn, soybean meal, wheat bran and other raw materials to meet specific process requirements. Required equipment:

(2)Raw material mixing: the prepared raw materials are fully stirred to improve the quality of the pellets.

(3)Granulation: feed the evenly-stirred raw materials into the poultry chicken feed pellet making machine for granulation (400-type feed pellet machine can also be used, or 300-type feed pellet machine can also be used, depending on the user's demand output for specific circumstances).

(4)Cooling: The temperature of the feed pellets after the granulation section is too high and easy to agglomerate. After cooling, the pellets are easy to be bagged for storage and transportation.

(5)Finished product packaging: Store the compressed feed pellets, that is, the finished product bags, in a ventilated place.

3. Layer feed processing equipment

(1)Cleaning Equipment: Drum Cleaner for Granule Pellets Cleaning, Powder Cleaner for powder material cleaning.

(2)Crushing Equipment: Chicken Poultry Feed Hammer Mill.

(3)Mixing Equipment: Dosing Scale,Feed Mixer Machine

(4)Pelleting Equipment:Multi poultry chicken feed pellet making machine

(5)Cooling Machine:SKLN Cooler

(6)Bagging Machine: manual bagging, semi-automatic bagging and fully automatic bagging.

For more information about laying hen feed, please directly consult Richi Machinery!

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.