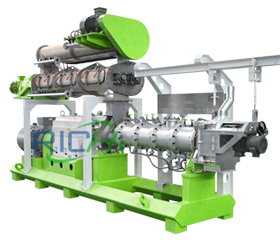

What is Double Screw Extruder Machine?

In recent years, the using of double screw extruder increases in the production of extruded pellets, the extruding principle if the same as single screw extruder. the difference is that the heat is not from screw extrusion materials resulting "strain hot", also set up a dedicated external heating and temperature control device, and a major role of screw is advancing the material. According engaging way of the screw, double screw extruder is divided into: counter-rotating engagement type, homonymous-rotating engage type, counter-rotating non-engage type , homonymous-rotating non-engage type.

Double screw extruder is segmented structure, according aquatic feed and pet food quenched requirements can increase or decrease the length of the extrusion screw sets to change the extrudate length of stay in the machine, the general requirements of the extrusion screw length to its diameter ratio range of 10:1 to 20:1.