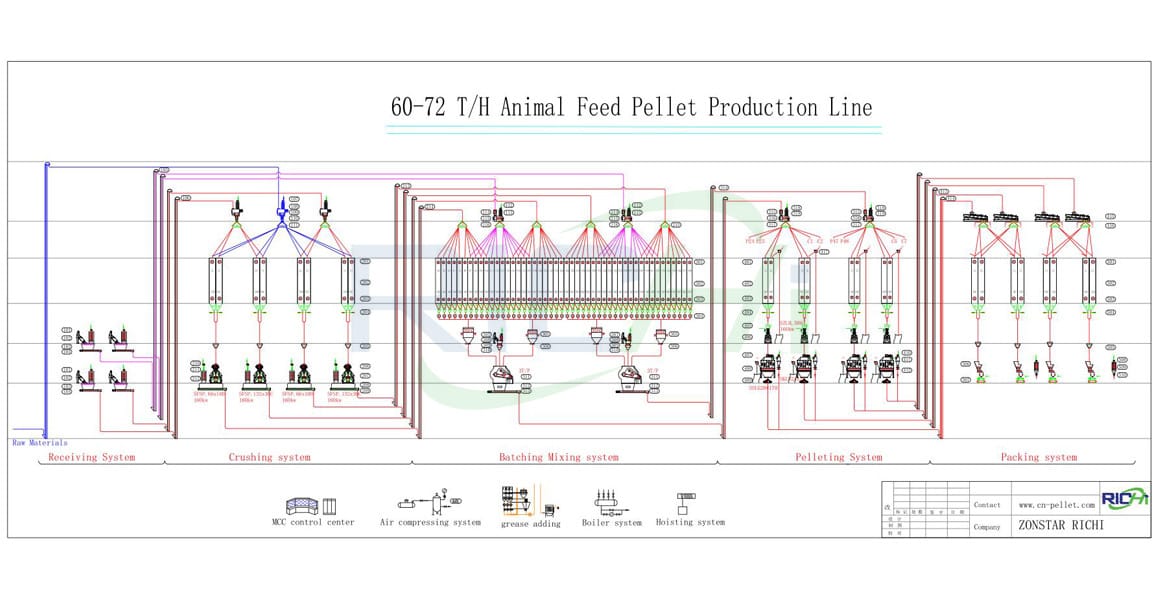

What are the advantages and disadvantages of crushing and then ingredients compared with ingredients and then crushing?

1. The advantages of crushing first and then ingredients

(1) The crushed materials are stored in the batching bin, so that the animal feed hammer mill crusher can always be in a full-load working state, and the utilization rate of the equipment is improved. In addition, the normal operation of subsequent equipment will not be affected when the crusher is repaired or maintained.

(2) The crushing variety is single, the management is convenient, the crushing efficiency is high, and the material is not easy to arch.

(3) When the output is large, the crushing process can be equipped with different types of crushers to improve equipment efficiency and reduce energy consumption.

2. Disadvantages of ingredients after crushing

(1) The smashed single material needs to be stored in a separate batching warehouse, and the corresponding investment will increase with the increase of the warehouse body.

(2) Due to the limited number of bins, it will be restricted when crushing a variety of materials.

(3) As the powder is stored in the silo, the possibility of arching is relatively increased.