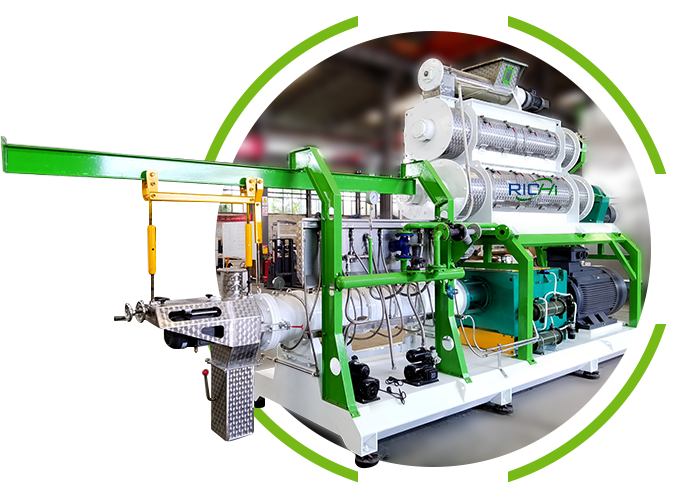

The Final Pellets Feed Of Fish Feed Making Machine

About The Raw Material

Every fish feed plant has a different formula. Usually the main raw materials for fish extruded feed are

soybean cake, soybean meal, wheat bran, fish meal, bone meal, starch, multivitamins, vitamin premixes,

special additives, etc.

About The Final Aquatic Feed Pellet

RICHI fish feed pellet making machine can produce a variety of different aquatic pellet extruded feeds,

if you have special needs, just contact us, RICHI will provide customizable aquatic feed extrusion

solutions.

*The size range of pellets produced by fish feed making machine is 0.6-20mm.