8-10T/H Complete Wood Pellet Production Line

Application: 8-10t/h biomass pellet plant is mainly suitable for the production of Logs,branches,sawdust, wood chips, wood shavings,straw,rice husk,organic fertilizer,peanut shell,palm trees,oil palm fronds,palm fiber,alfafa,sugar cane bagasse,forestry waste,hops,wheat stalk,hemp,palm kernel shell,waste paper,etc.

Customer type: 8-10T/H biomass pellet production line is specially designed for all manufacturers based on the principle of biomass recycling, such as biomass fuel manufacturers, wood board factories, organic fertilizer factories, feed factories, carton factories, etc.

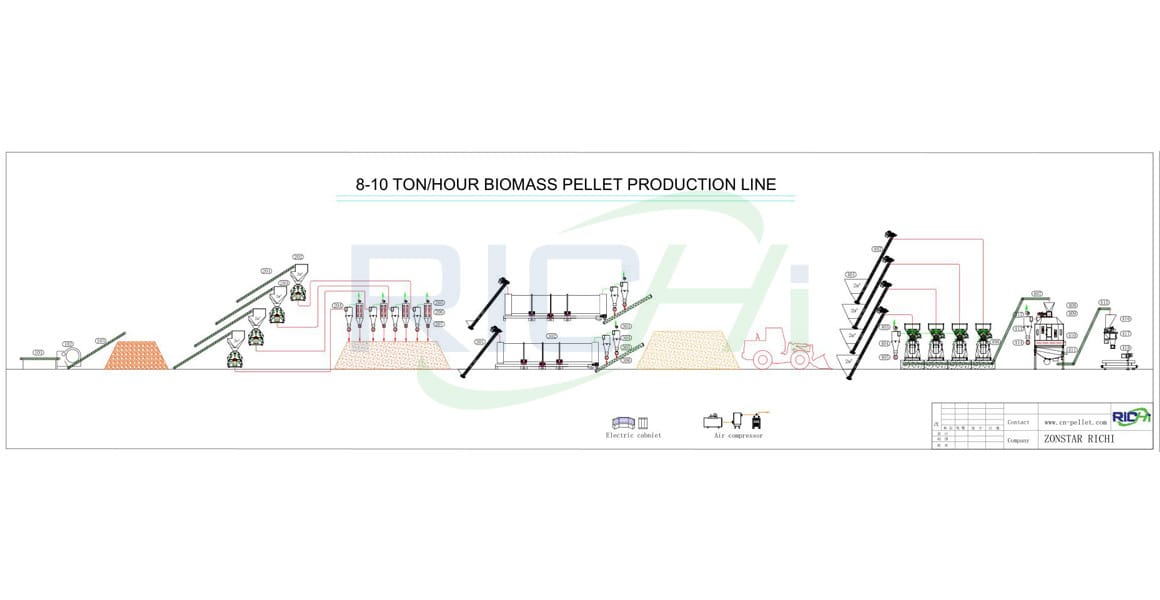

Processing technology: The main processing flow of 8-10t/h biomass pellet production line: raw material receiving and cleaning system, crushing,mixing, pelleting,dying,cooling, screening, packaging. This is just the general 8-10t/h wood biomass pellet process, according to different biomass types, different output configuration can be customized.

Main machine: The main equipment of a complete 8-10 tons per hour wood biomass pellet processing plant includes grass crushing machine, biomass pellet mill,wood mixer machine,counter-flow pellet cooling machine, wood chipper machine,box cylinder pulse dust remover, vibrating screen classifier,belt conveyors,rotary dryer,automatic bagging system,electric control cabinet,etc.

SZLH-508 Feed Pellet Machine

SZLH-508 Feed Pellet Machine  SKLN Series Counterflow Cooler

SKLN Series Counterflow Cooler  SLHJ Feed Mixer Machine

SLHJ Feed Mixer Machine  SFSP Animal Feed Crusher

SFSP Animal Feed Crusher