How to built a 15t/h commercial pig animal feed mill factory?

How to built a 15t/h commercial pig animal feed mill factory? Today we will use an animal feed production case we have done to tell you how to build a high-quality and high-return 15t/h pig animal feed mill factory.

1.Process of building a complete commercial pig animal feed factory 15 tons per hour

(1) Determine the processing scale of the commercial animal feed factory for pigs

(2) Determine the feed processing technology and select related pig feed making equipment

● Product variety, quality, and output requirements;

● Formula for pig animal feed production;

●Production technology and animal feed processing machine for pig feed;

●The performance and quality of the animal feed making machine for pig feed;

●Cleaning and maintenance of animal feed manufacturing machine for pig feed;

●Animal pig feed production cost and usage cost;

●Standardization, serialization and generalization of parts and components;

●The construction space of the 15 tons per hour animal feed factory project;

●Environmental protection, fire protection and other national rigid requirements.

(3) Selection of 15t/h commercial pig animal feed mill plant control mode

●Capacity

●Complex and simple craftsmanship

●How many product varieties

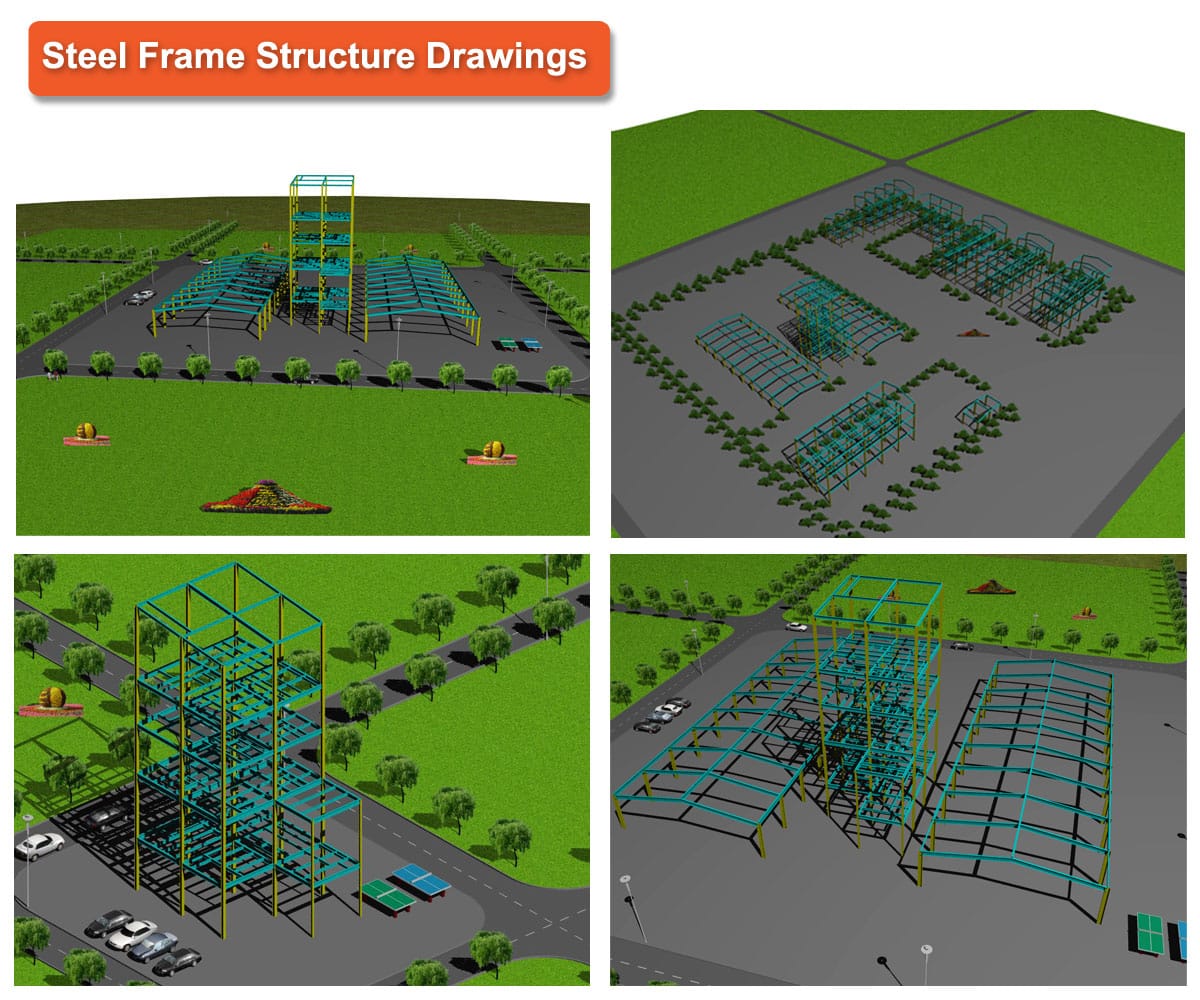

(4) Selection of the structure of the 15t/h commercial pig animal feed plant factory

Full concrete structure/semi-steel structure/all steel structure, etc.

(5) Planning the general layout of the 15t/h commercial pig feed factory area

The overall layout of the 15t/h feed mill varies according to the nature, scale and technological process of the feed mill. usually:

●Buildings should account for 30-35% of the total area of the 15tph animal feed mill factory.

●Factory roads account for 13% of the total area.

●The green area is not less than 10-15% of the whole 15 tons capacity pig animal feed factory area.

2. [Case analysis] Complete 15tph animal pig feed production factory turnkey project report

(1) The scale of the 15t/h commercial animal pig feed production factory

In the first phase, a 15t/h pig feed factory will be established. The civil works are designed according to two feed production lines and completed at one time. One pig feed processing equipment is installed in the first phase and one is reserved.

(2) Product types and specifications of 15t/h complete animal pig feed plant

It mainly produces complete pig feed pellets for breeding boars, breeding sows, pregnant sows, suckling sows, suckling pigs, piglets, growing pigs, fattening pigs and other pigs.

(3) 15T/H commercial animal pig feed manufacturing factory location

① Site selection

The selected area of the 15t/h pig feed production project is non-production arable land, about 60 acres. The front of the pig feed making factory is the Mianyu Provincial Highway, which has convenient transportation and is across the road from the customer's original breeding farm. There is no residential housing around the site and the environment is good. There is an overhead dedicated line power supply above the site with sufficient power.

②Geological conditions

The animal feed factory site has good geological conditions, high terrain, a certain slope, and smooth drainage. However, due to its location on a sloping land and far away from the Fujiang River, the cost of basic works such as laying water pipe networks and surface leveling is relatively high.

(4) 15T/H animal pig feed manufacturing plant layout planning

①Pig feed factory buildings and facilities

★Pig feed factory production workshop: pig feed processing workshop (main workshop) and premix processing workshop.

★Pig feed factory auxiliary workshop: electromechanical, instrument repair, weak current control room, laboratory, etc.

★Pig feed factory Warehouse: pig feed making raw material warehouse, vertical silo warehouse (steel warehouse), finished product warehouse, equipment warehouse, etc.

★Pig animal feed factory power facilities: power distribution room, boiler room, air compressor station, etc.

★Pig animal feed factory administrative living buildings: administrative buildings, canteens, dormitories, bathing halls, etc.

★Pig animal feed factory Transportation facilities: roads, garages, etc.

★Engineering technology pipeline network: various pipelines such as water supply, power supply, compressed air, steam, etc.

★Greening facilities and architectural sketches: fences, gates, guard rooms, pools, lawns, flower stands, publicity bulletin boards, bicycle sheds, disinfection pools, fire-fighting facilities, etc.

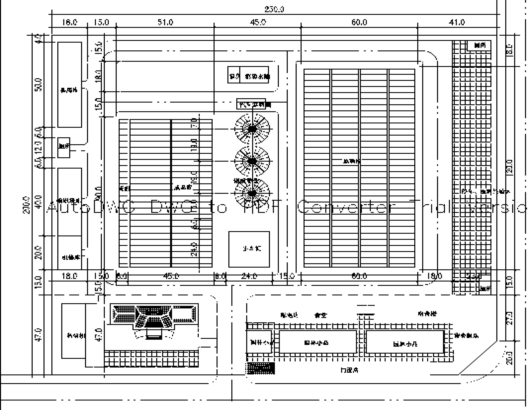

②The general layout of the 15 tons per hour commercial animal feed factory for making pig feeds

③Design principles and characteristics of the 15 tons per hour pig feed factory layout

★It meets the requirements of the 15t animal pig feed production process, highlights the main project, and the pig feed production line is smooth, continuous and short, avoiding the crossover of the work line.

★The raw material warehouse and the finished product warehouse are centrally arranged around the main processing workshop, and the vertical silo is convenient for loading and unloading mechanization and dumping and saving land.

★The main processing workshop is a multi-layer reinforced concrete structure, and fully considers the relationship between the azimuth shape and the dominant wind direction and sunshine, and has good natural lighting and natural ventilation.

★The administrative building, office and laboratory, medical office, dormitory, etc. are merged to live in a quiet and clean place.

★The canteen, boiler room, etc. are arranged with the downwind of the factory area, and the compressed air is arranged near the load center and away from the clean upwind of the living area.

★The transportation in the 15 ton animal feed factory for pig feed making is convenient and flexible. The entrance and exit of the animal feed production plant area are double-lane, 8 meters wide, the fire channel is not less than 3.5 meters, the sight distance for meeting cars in the factory is not less than 20 meters, and there is enough distance from the edge of the road to the building: 1.5 meters from the fence, 1.0 meters from the trees, 1.0 meters from the lighting poles , 3.0 meters from buildings without entrances and exits, and 6-8 meters from buildings with entrances and exits with car lanes.

★Logistics balance: The 15t/h animal feed mill factory has a daily transportation capacity of about 150 tons of raw materials for pig feed, and the logistics direction and other pipeline network transportation lines are reasonably configured according to the requirements.

★Properly leave room for future development.

④Main technical and economic indicators of the general layout of the 15t/h animal pig feed pellet processing factory

★Plant area (inside the enclosure): 46000m², building area (including all buildings and roads): 16000m². Among them: raw material warehouse: 7200m²; silo: 1200m²; main workshop: 12116m²; finished product warehouse: 4000m²; green area: 4000 m²; total road length (calculated based on the center line of the car-accessible roadway in the pig feed mill line factory): 1350m.

★Site utilization factor: the sum of building area/total area of the site=16000 /20000 =80%

★Building factor: the total area of covered buildings/total area of the site = 8000/ 20000 = 40%

★Greening coefficient: Greening area/total area of the site = 4000/20000 = 20%

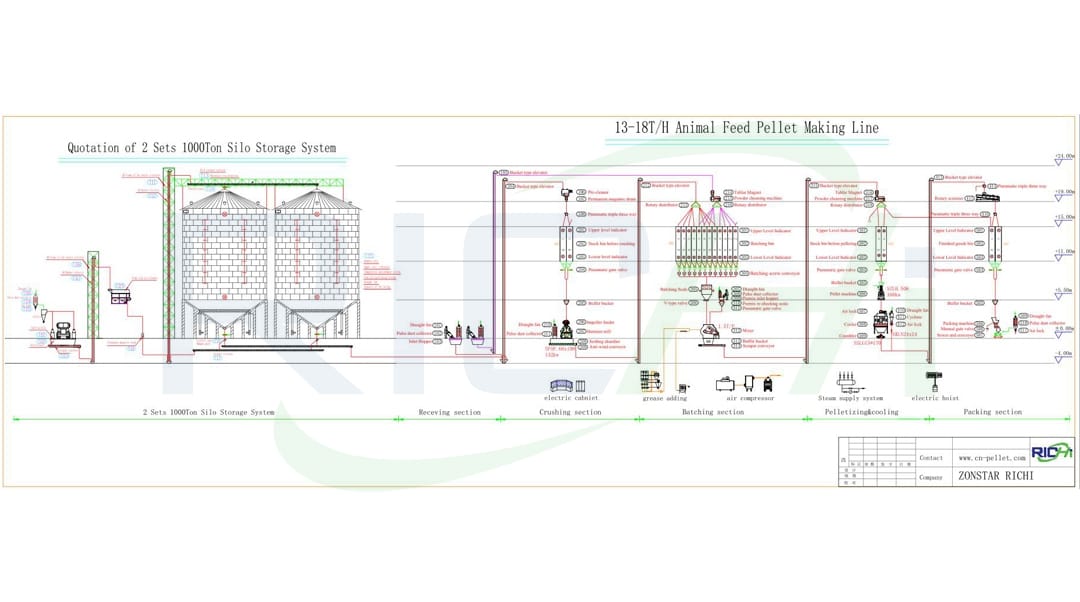

(5) Process design of 15 tons per hour commercial animal feed factory for pig feed pellet and powder production

★Main workshop design

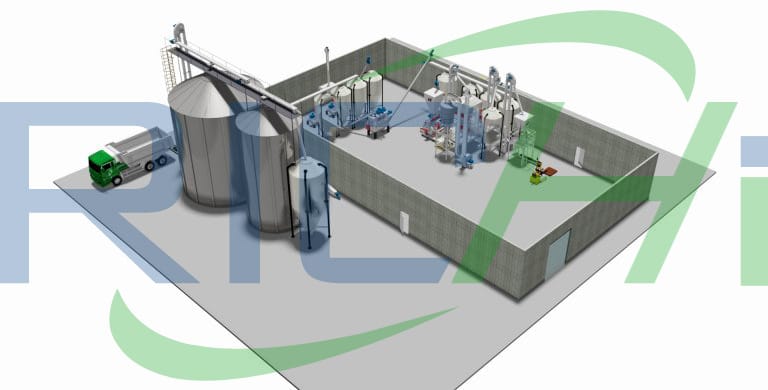

The 15t/h pig feed plant mainly produces powdered compound pig feed and granular compound pig feed. According to the pig feed formula and the pig feed processing requirements and delivery methods of various raw materials for pig feeds, the 15t/h feed plant process design for pigs adopts advanced pig animal feed mill process flow and animal feed processing equipment, which has good adaptability and flexibility. The use of serialization, standardization and generalization of parts is reliable in operation, which is conducive to continuous operation and reduces 15t/h animal feed manufacturing factory production costs.

Various pig animal feed mill machinery and equipment is reasonably arranged according to the specific conditions of the structure of the plant, and the compact arrangement is not only conducive to operation, maintenance and management, but also saves area, is practical and beautiful. The 15 tons capacity pig animal feed production line is reserved in the same workshop with the equipment of the first phase, and the interface is reserved. In the case of fully capable of producing high-quality various pig feeds, you can consider sharing some pig feed equipment with the first phase to ensure the complete pig feed manufacturing process and pig feed equipment layout, which is convenient for the architectural design in one step .

①The main pig animal feed production equipment, such as animal feed grinding machines, batching scale, animal feed mixers and pig animal feed pelletizers, are placed close to the window, which is conducive to lighting and operation. Bag filters, ventilators, cyclones and other animal feed making equipment can be placed in the lighter-poor place.

② Equipment with heavy weight and high vibration (such as animal pig feed grinder machine) should be placed on the ground floor or basement of the workshop and isolated, which is good for sound insulation and fire prevention.

③The unloader and dust removal equipment for pneumatic conveying materials are placed on the highest floor of the workshop.

④ Configure the same feed making machines on the same floor to facilitate unified operation and reduce the frequency of material lifting.

⑤The batching warehouse is set on the upper layer of the feed batching equipment, and the animal feed mixing equipment is arranged on the lower layer of the batching equipment, and a wide operating distance is left to facilitate the addition of trace components, sampling inspection and cleaning of internal residues.

⑥The animal feed pelleting machine for pig pellet feed is arranged on the upper layer of the cooler, and the hot and humid particles out of the machine directly enter the cooler.

★Warehouse design of 15 tons per hour capacity pig animal feed production

① Silo: made of galvanized steel, with a capacity of 2000t/piece, two in total, diameter: 10m, height: 18m.

②Powder storage: light steel structure, area: 50m×80m=4000m2.

③Finished product warehouse: light steel structure, area: 50m×60m=3000m2.

★Laboratory design

According to the product quality requirements of the feed factory, all raw materials and products that enter the factory will be randomly inspected to ensure that unqualified raw materials will not enter the factory and unqualified products will not leave the factory.

①The main 15t/h animal feed factory equipment of the laboratory

The main analytical and testing instruments are: Sample crusher, balance, electric furnace, muffle furnace, oven, centrifuge, incubator, water bath, acidity meter, colorimeter, spectrophotometer, microscope, agitator, refrigerator, sterilization pot, feed nutrient analyzer, common glass food equipment and utensils, etc.

(6)Feed machinery for pig animal feed mill factory with 15t/h capacity

★ Overall technical requirements for pig animal feed factory equipment configuration

①The 15t/h feed plant equipment is stable and reliable, and adaptable. Imported or joint venture products are used for key components such as motors and electrical appliances.

②All 15t/h pig animal feed factory equipment in the system is closed to prevent material leakage and dust from entering, and set up observation holes and light sources for observation.

③All 15t/h pig animal feed factory equipment adopts metal structure or engineering plastics or engineering materials of the same grade.

★Main pig animal feed factory production equipment (see the detailed list of equipment configuration and production equipment investment in each process of the process specification)

★Auxiliary animal feed production equipment

①Conveying machinery for 15t/h commercial pig animal feed mill factory: belt conveyor, buried scraper conveyor, screw conveyor, bucket elevator, pneumatic conveying, chute, chute, rotary distributor, etc.

②Silo for 15t/h commercial pig animal feed mill factory: pig feed raw material warehouse, smashing warehouse, batching warehouse, finished product warehouse, buffer hopper, etc.

③Ventilation and dust removal system for 15t/h commercial pig animal feed mill factory: dust collection device → air network → fan → dust removal device (cyclone separator, bag filter, etc.)

The dust removal pipeline and cyclone separator are made of galvanized steel sheet or other anti-corrosion materials, and the support is made of galvanized steel sheet.

A. The dust collection device of the 15 ton feed making factory is not only used to suck dust, but also to complete tasks such as cooling, moisture absorption and separation of light impurities. The design and selection of dust collection devices consider the following points: the dust removal device should be as sealed as possible to the dust source, and Reduce the scope of the dust source while avoiding the dusty air flow center to prevent a large amount of powder (material) from being sucked out;

B. The suction port of the dust suction device is directly opposite and close to the place where there is a lot of dust, and the suction direction should be as consistent as possible with the direction of the dusty air;

C. The form of the dust suction device should not hinder operation and maintenance;

D. The suction surface should have sufficient size, the suction speed should be 3~5 m/s for grain and 0.5~1.5m/s for powder.

④Steam supply system for 15t/h commercial pig animal feed mill factory:

Boiler → steam → sub-cylinder → steam equipment

The boiler evaporation capacity is 2t/h, the sub-cylinder pressure reducing valve requires imported products, and the test pressure is ≥1.5MPa. The steam pipeline uses seamless steel pipe with a wall thickness of 6.5≥mm, and is wrapped with rock wool for insulation.

⑤Air compressor system for 15t/h commercial pig animal feed mill factory: air compressor→air storage tank→air dryer→air equipment

The compressor displacement is 2m3/min, the compressor pressure is 0.7~1.0 MPa, the gas storage tank capacity is 2m3, and the gas storage tank pressure is 1.0 MPa.

It can carry out status monitoring, low vibration and noise, and is permanently free of lubricants.

⑥Water supply and power supply system for 15t/h commercial pig animal feed mill factory:

The voltage of the 15 tons pig feed factory is 380V, 52Hz, three-phase power supply, and the voltage fluctuation range is ±10%.

The water supply network is connected to Tuopai Industrial City.

⑦Total installed capacity for 15t/h commercial pig animal feed mill factory: 1630W.

(7) Analysis of 15 ton/hour commercial pig feed plant investment cost

The estimated total investment of the 15 ton commercial animal feed factory for pig is as follows:

| Item | Civil works | Infrastructure | Animal feed production equipment | Testing Equipment | Working capital | Other |

| Investment (ten thousand yuan) | 500 | 100 | 350 | 65 | 4000 | 105 |

The above content is some of the main indicators of this 15t/h turnkey pig animal feed manufacturing project. In addition, there are the demand for various raw materials in the feed factory, the demand for various raw materials in the 15tph turnkey feed factory, environmental protection and safe production, organizational structure and labor quota, organizational structure and labor quota, Personnel training, feed production process specifications, feed processing equipment operating procedures, pig feed equipment operating procedures, total quality management system, financial system and other details. If you want to know more, please don't hesitate to contact Richi Machinery——customized feed machinery supplier from China.

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.