How to set up feed company 20 tons per hour for poultry feed?

How to set up feed company 20 tons per hour for poultry feed? There are some basic procedures for building a 20t/h poultry feed company, and some application conditions must be met. Of course, it also involves the location and process of 20t/h animal feed companies , Design and selection of poultry feed manufacturing equipment. Today Richi Machinery will bring you the most detailed 20 tons per hour animal poultry feed company construction process and basic 20t/h animal poultry feed company business plan.

Establishment and declaration of 20 tons per hour poultry feed company

How to set up feed company 20 tons per hour for poultry feed? First, determine the basic procedures for establishing a 20 tons per hour poultry feed company and obtain the approval of the relevant department of the local government.

- Determine whether to build a new 20/h poultry feed company (is it feasible to create a poultry feed company? What issues should be considered?)

- Make a feasibility report (based on the results of the investigation and forecast, the investor makes an investment intention for poultry feed company 20tph.)

- Propose a long-term development plan for the 20t/h poultry feed company (if there is no long-term plan to build a 20 tons capacity poultry feed company factory, it may result in the need to relocate due to the unified planning of the local government just after the establishment of the 20t/h animal feed company)

- Approval of 20tph poultry feed company feed production license and product approval number. Submit the 20t/h automatic poultry feed company plant construction application and feasibility report to the local agriculture and animal husbandry management department before building the 20t/h automatic poultry feed company → agriculture and animal husbandry management department → agriculture and animal husbandry administrative organs → 20t/h automatic poultry feed company construction → apply for the inspection and acceptance of the agriculture and animal husbandry administrative organs and receive the "feed production license application form" →"Get Feed Production License"

- Handle the approval document number of feed additives and additive pre-mixed feed products. Is the 20tph poultry feed company able to produce feed products after the "Feed Production License" has been processed in accordance with the prescribed procedures? The answer is No. After the 20t/h poultry feed company obtains the production license issued by the Ministry of Agriculture, it must receive the "Application for Approval Number of Feed Additives and Additive Premixed Feed Products", then submit materials and feed samples, and send the products to the designated testing agency for testing feed quality. After passing the test, the approval number of 20t/h poultry feed company feed production will be issued.

Complete 20t/h animal poultry feed company design

After the 20t/h poultry feed company construction project is approved, the pre-design work and design work become the key to the 20t/h poultry feed company construction. Design work plays a decisive role in speeding up the construction speed, ensuring the quality of construction and installation, saving investment, and obtaining the maximum economic and social benefits after completion.

The 20t/h poultry feed company design is an important part of the basic construction of the feed industry. Design work is inseparable from the development and industrialization of new processes, new technologies, new poultry feed equipment and new products, whether it is the new construction, reconstruction and expansion of 20t/h poultry animal feed companies. After the 20t/h poultry feed company construction project is approved, the pre-design work and design work become the key to the 20t/h poultry feed company construction. Design work plays a decisive role in speeding up the construction speed, ensuring the quality of 20t/h poultry feed company factory construction and installation, saving investment, and obtaining the maximum economic and social benefits after completion.

(1) Design scope of whole 20t/h poultry feed company

Generally speaking, the design scope of a 20t/h poultry feed company mainly includes all the engineering projects produced by the factory and the necessary projects outside the factory, such as railways and highways. mainly includes:

- Complete 20t/h poultry feed company layout plan design

- Poultry feed production process design: the formulation of 20t/h poultry feed company process flow and poultry feed production equipment selection, workshop structure and equipment layout design, transportation network and ventilation and dust removal network design, workshop self-made equipment and facilities design, poultry feed company warehouse layout design, etc.

- Auxiliary production system: design of steam supply system and compressed air system, electrical engineering design, water supply and drainage engineering design, environmental protection engineering design and poultry feed machine repair workshop design, etc.

- Information system: design of laboratory testing system and production automatic control system.

- Civil engineering: design of buildings and structures in the 20t/h poultry feed company, master plan design and road design of the 20t/h poultry feed mill company, etc.

(2) Factors that should be considered in 20t/h poultry feed company factory design

When designing the 20t/h poultry feed company factory, the external factors and internal factors of the factory must be considered, including:

Geographical factors

Geographical factors include topography, topography, geology, status and other factors. Geographical factors affect the overall layout design and layout of the 20t/h animal poultry feed company, water supply and drainage system design, civil engineering design, transportation route design and product cost.

Climatic factors

Climatic factors include temperature, humidity, wind direction and hydrology. Climatic factors affect the storage of raw materials and products, whether the environment of the operators requires temperature adjustment equipment, whether the storage and processing of raw materials and products require dehumidification or drying equipment, general layout and environmental protection engineering design, water supply and drainage system design and civil engineering design.

Factors of poultry feed raw materials and power resources

The raw material factors mainly affect the poultry feed company process design and the determination of the production regulations; the power factor affects the 20t/h poultry feed company process design and auxiliary design.

Social factors

Social factors mainly refer to labor, taxation, interest rates, laws and regulations, regional planning and culture.

In addition, the 20t/h poultry feed company plant design should also consider the relationship between personnel and materials, the relationship between personnel and equipment, the relationship between materials and equipment, the relationship between equipment and equipment, the relationship between materials and materials, and the relationship between personnel and personnel. Factors within the factory such as the relationship between personnel, materials, equipment and space.

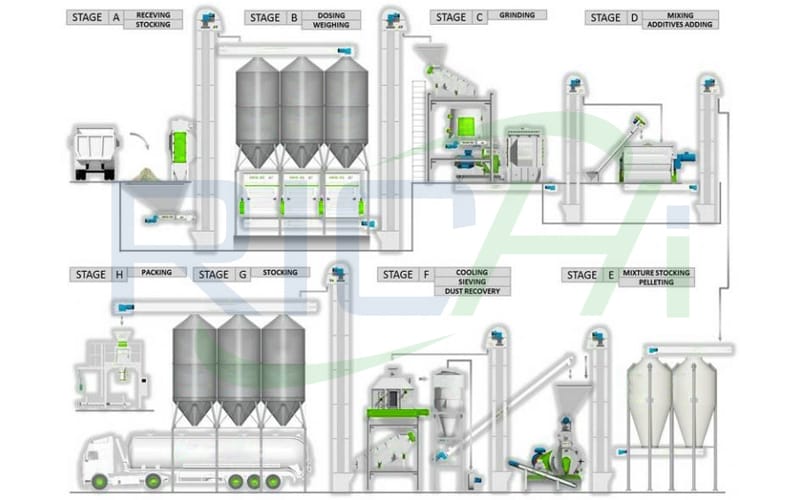

Production process and poultry feed machinery for animal feed company 20 tons per hour for poultry feed?

(1) Raw material receiving and cleaning section for 20t/h poultry feed company

In this section, the pellet feeding cleaning and powder feeding cleaning are separated independently, and the dust is removed separately, and the dust removal effect is good.

Cleaning equipment : SCY80 granular material sieve, designed to produce 20-30T/H per hour; powder sieve SQLZ60×50×100, designed to produce 10-15T/H per hour.

(2) Crushing section for 20t/h poultry feed company

This section adopts two poultry feed grinders, each poultry feed grinding machine is equipped with two smashing bins, which can crush different raw materials at the same time to improve production efficiency. Before the raw materials enter the warehouse, impurities are removed by a magnetic separator to ensure the safe operation of the crusher.

Crushing equipment (2 sets): poultry corn feed hammer mill crusher SFSP668×800, 110KW, with a design output of 10-15T/H per hour.

(3) Batching mixing section for 20t/h poultry feed company

This section adopts 16 batching bins, two batching scales are used for batching at the same time, controlled by the batching program independently developed by our company, to realize accurate fast and slow feeding, fast batching speed and high precision.

Weighing equipment: batching scale PCS20/PCS10, batching accuracy: dynamic ≤ 3‰, static ≤ 1‰. Mixing equipment: poultry feed mixer SHSJ4, (30KW, 2000kg/batch), designed to produce 20-30T/H per hour. Mixing uniformity CV≤5%.

(4) Pelleting section for 20t/h poultry feed company

This section adopts two double-layer quenched and tempered poultry feed pellet making machines, and each poultry feed pelleting machine is equipped with two silos to be granulated, which makes it easy to switch between varieties. After granulation, it enters the cooler, the crusher, and the elevator into the rotary grading sieve in order for screening. The finished product enters the packing bin, the powdered material is screened out and returned to granulation, and the large particle material is screened out and returned to the poultry feed crusher for crushing.

Poultry feed pelleting equipment (2 sets): SZLH420 (110KW), designed to produce 10-12T/H/set per hour. Cooling equipment (2 sets): SKLN6, designed to produce 10-15T/H/set per hour.

(5) Packing section for 20t/h poultry feed company

There are 4 finished product warehouses in this section, of which 3 warehouses are dedicated to storing finished pellets, and one powder and pellets can be stored. The powder finished product warehouse is designed with a unique anti-classification device. The pellets or powders are finally automatically weighed and packaged by the packaging scale.

Packing equipment: belt scale (both powder and granular materials), packing range 20-50kg/bag, 6-8 bags/min.

(6) Auxiliary section for 20t/h poultry feed company

Dust removal system to improve the working environment of workers; grease addition system, which is added at the common mixer to improve the palatability of poultry feed.

(7) According to the needs of different customers, the scheme can be optimized for configuration:

- This scheme adopts a single-point dust removal mode, that is, each rotary distributor (powder) and pellet cleaning screen is equipped with a pulse dust collector, which has a good dust removal effect. Single-point dust removal is a humanized design for our company and provides a better working environment, but the cost increases. Customers can consider whether to adopt this configuration according to actual needs;

- The number of silos can also be adjusted according to the customer's poultry feed formula, the characteristics of the poultry feed making raw materials and other factors to achieve the highest utilization rate and effectively control the production cost;

- The pellet crumbler machine after the poultry feed pellet cooler can be selected. If the crushing volume is not particularly large, you can consider the plan of reserving one for the previous one;

- The finished product can be equipped with bulk storage according to the needs, and the finished product can also be equipped with mechanical palletizing.

How much to set up feed company 20 tons per hour for poultry feed?

Cost to set up feed company 20 tons per hour for poultry feed is 250000-580000USD.

(This 20 tons per hour poultry feed company investment cost refers to the price of the production line equipment. Due to the different construction needs of customers for the 20t/h poultry feed company, the investment cost varies greatly. Please directly consult Richi Machinery to customize your 20 tons per hour feed company for poultry feed production.)

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.