RICHI chicken feed pellet line used for production the different size chicken feed pellet, such as 1.5mm small baby chicken feed pellet , 3-4mm broilers and laying hens feed pellet, and others you need size. Can be customized according to your detail requirement. The main machines of feed pellet line is chicken feed pellet machine, feed hammer mill, feed mixer and others

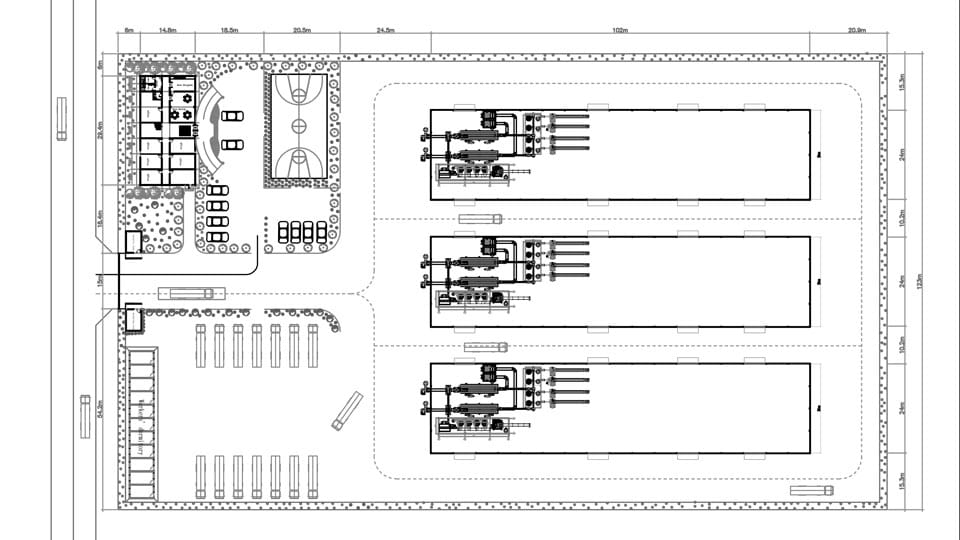

Our solutions come in a modular design so you can customize them to match your production process. At RICHI we focus on solutions that pay off, whether it's supplying the smallest spare part or serving as a long term partner. Complete Chicken Feed Pellet Line includes the following equipments, from the storage of raw materials to the packaging of the final pellets. Each section has professional equipment to work. Of course, according to the different needs, it may be the particularity of the raw materials or the limitations of the site. Our engineers will redesign the process, and the equipment used will be increased or decreased. Click each module below, you will see the specific equipment information.

1

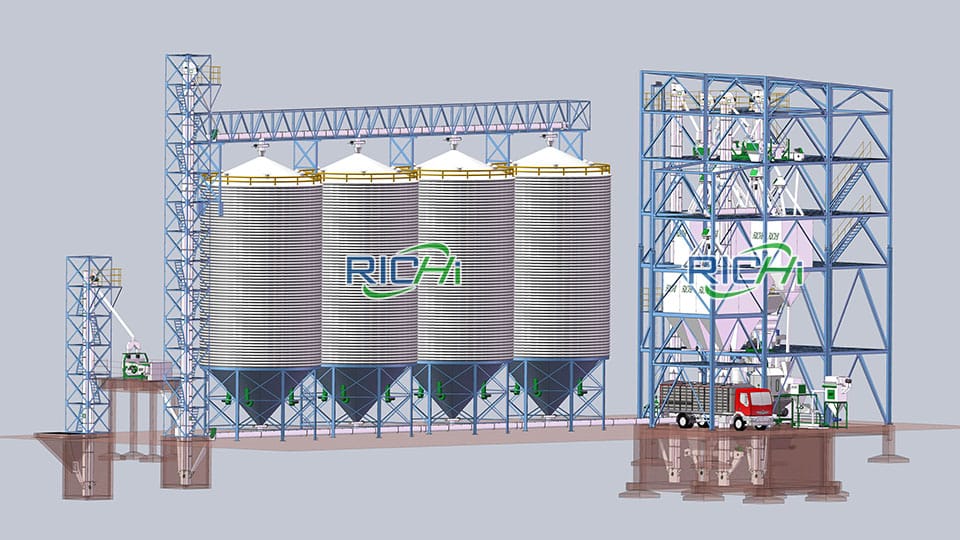

This is the storage section of the complete chicken feed pellet line.

Because the chicken feed raw materials of the feed are dispersed, especially when the production capacity of chicken feed pellet line is very large and need for automatic control system. So various forms of silos must be used, It can solve the problem of manual feeding and storage of raw materials.

Silo system is mainly used for storage of corn, wheat, soya and other raw grain in this chicken feed pellet line, port of raw grain dumping, grease industrial materials storage.For long-term storage, aeration and cooling can be added.Generally,steel silo can be divided into assembly type steel silo and screw type helix steel silo.

2

This is the receiving section of the complete chicken feed pellet line.

The chicken feed raw material receiving system of chicken feed pellet line includes bulk raw materials, packaging raw materials, and liquid raw materials. Bulk raw materials are weighed by dump trucks and weighed before unloading the raw materials to the silo; packaging raw materials are divided into manual handling and mechanical handling; liquid raw materials are directly transported into the warehouse in the form of bottles or barrels.

3

This is the pre-cleaning section of the complete chicken feed pellet line.

The usage of cleaning system of chicken feed pellet line is removing the chicken feed raw materials’ impurities, such as rope, clod, corn cob etc. non-magnetic impurities and iron nail magnetic impurities. It can ensure the quality of final chicken feed pellet products and the safety of the subsequent processing equipment.

4

This is the crushing section of the complete chicken feed pellet line.

Before making chicken feed pellet, the raw materials should be grinded. The chicken feed hammer mill can grind the raw material ingredients to the required size.(Chicken feed should not be too fine, because chickens like to eat pellet feed or crushed grain feed, which can be used in combination with thickness. Rice and broken rice can be directly added to the mixer in granular form. The crushing fineness of wheat and barley should be below 2.5 mm. Corn, brown rice and bean cake should be processed into powder.)

5

This is the mixing section of the complete chicken feed pellet line.

Mixing is considered to be one of the essential operations in chicken feed pellet processing, The mixer is the main machine in the chicken feed pellet line. It using mixer to mix the grinded raw materials. There are three types of our mixer: single shaft mixer, double shaft paddle mixer and ribbon mixer. Both of them can be equipped with atomizing spraying system to add needed liquids, which can improve the chicken feed pellet quality.

6

This is the pelletizing section of the complete chicken feed pellet line.

Chicken Feed Pellet Machine is the key equipment of chicken feed pellet line. The purpose of pelleting system is to solve the finely divided, dust-prone, poorly palatable and difficult-to-ship chicken feeds into granule pellets by the action of heat, moisture and pressure in the pelleting process. It can improve the palatability of the chicken feed, reduce the feed-meat ratio, reduce feed waste and reduce environmental pollution.

7

This is the cooling section of the complete chicken feed pellet line.

After the chicken feed pelletizing process, the temperature of the feed pellet is about 80-90℃,with a moisture content of about 15%.A cooling machine must then be used to reduce the moisture content of the pellets to about 3/4%,thereby making the pellets easier to store.

8

This is the crumbling section of the complete chicken feed pellet line.

Crumbling section is optional of the chicken feed pellet line. It is special purpose equipment to crumble big chicken feed pellets into small pellets.(In order to save electricity, increase output and improve quality ,in the production process of the pelletizer, the material is often made into pellets of a certain size, and then crumbled into qualified products by the crumbler according to the pellet size of the chicken feeding.)It is used for production the 1.5mm feed pellet for small baby chicken.

9

This is the screening section of the complete chicken feed pellet line.

The rotary screener is equipped with two layers of screens so that can separating out three different materials, the largest material closest to the final outlet, and then the qualified materials and powder materials in turn; The large material will be fed to the crumbler for crushing, the qualified material will be fed into the finished product bin through the three way, and the small powder material will be fed into the pellet machine for again pelleting work;

10

This is the packing section of the complete chicken feed pellet line.

The automatic packing system is composed of packing scale, belt conveyor and sewing machine. It can packing into 10-50Kg bags. Packing machine will package thechicken feed pellets into bags with different specifications based on requirements. The final chicken feed pellets will be stored properly.

11

This is the conveyor section of the complete chicken feed pellet line.

Our conveyor system cover all applicatons thoughout your chicken feed value-added chain,from raw material intake to conveying finished chicken feed pellets.We customize a system to meet your sapce and process needs,using any combination of elevators,through chain,belt and screw conveyors.

RICHI can provide the complete turnkey project feed pellet production line, from design to install . Whether you want to produce chicken feed, cow feed or pig feed, the capacity is 1-100TPH can be choose. The main machine is feed hammer mill, feed mixer, feed pellet machine , cooling machine ,rotary sereener and others . Looking forward to your consultation !

Name: The

10T/H Automatic Chicken Feed Pellet Line

Country: Uzbekistan

Pellet Size:2-4mm

Main Material: Corn, wheat, Soybean Meal, and other Grain

Total Power:358KW

Main Machines: 1.Feed Hammer Mill*110kw;2. Batching Scale *1000kg/batch 3.Feed

Mixer*1000kg/batch ;4.Chicken Feed Pellet Machine*110KW;5.Cooling Machine*SKLN20*20;

6.Crumbler Machine*SSLG15*150 ;7. Vibrating Sereen ;8. Packing System and other auxiliary

equipment.

The field trial operation proves that the actual measured output of RICHI's 10t chicken feed pellet line is up to 13 tons, the operating current only accounts for 85% of the rated current of the motor, and each ton of feed can be 20kW•h less than the industry average power consumption. The output is calculated on the average yield of 11t/h (the initial design capacity is 10-12 tons), set to produce 8 months a year, 30 days per month, and 10 hours per day.Compared with common chicken feed pellet line of the same grade in the industry,this line can save 288,000 kWh of electricity,one yuan per kwh can ultimately save customers 28.8 million (calculated in RMB).

Send Inquiry

Name: 10T/H

Cattle Feed Pellet Production Line

Country: South Africa

Pellet Size:1-12mm

Main Material: corn, soybean meal, 50% grass and other grain

Total Power:335KW

Main Machines: Feed Hammer Mill*110KW, Feed Mixer*1000KG/BATCH, Batching

Scale*1000KG/BATCH, Feed Pellet Machine*110KW,Pellet Cooling Machine*SKLH20*20, Crumbler

Machine*SSLG15*150, Screen Machine, Automatic Packing Machine, Coal-fired Boiler*0.7MPA,

etc.

This project is currently the most advanced ruminant feed production line in the customer's local area. The project is fully computer-controlled and replaces the customer's previous manual packaging, manual handling, manual baching, and manual operations, allowing customers to experience the efficiency, energy saving, and safety of automated feed production. At the same time, the project uses a first-class process plan, the rumination process uses the most advanced production equipment in South Africa, which greatly improves the production efficiency of customers and creates economic value for customers.

Send Inquiry

Name: 5T/H Extruded Shrimp Feed Pellet Production Line in Henan

Country: China

Pellet Size:0.6-4mm

Main Material: fishmeal,homemade fishmeal, alcohol master batch, soybean phosphatide,

soybean meal, peanut meal, etc

Total Power:235KW

Main Machines: Fish Feed Grinder, Feed Ultra-fine Pulverizer, Feed Mixing Machine,

Pellet Crumbler, Automatic Batching System, Fish Feed Extruder Machine, Feed Pellet Cooler,

Screen Machine, Automatic Packing Machine, Natural Gas Boiler, etc.

The extruded aquatic project is the largest local aquatic project of the client. Its successful operation not only brings great changes to local farmers, but also lays a stable foundation for the long-term development of RICHI. The use of differentiated process equipment for this expanded aquatic project will greatly improve feed quality and profitability; at the same time, the introduction of automation and intelligent equipment will also greatly reduce labor costs, help customers improve efficiency, and reduce feed plant operating costs . During the construction process, not only advanced technology is introduced into the local area, but also resource and energy utilization are considered, so that the project saves electricity and steam.

Send Inquiry

RICHI chicken feed pellet machine is the main machine used for production the chicken feed pellet. If you want to production chicken feed, we can provide the chicken feed machine ,also can design the complete chicken feed pellet production line for you.

We also can provide the chicken feed formula for you.

Soybean meal 53% ; Cotton seed meal 18%

Rape-seed cake 4.1% ; Maize protein meal 8%

DDGS(distillers dried grains with soluble) 4%

Calcium bicarbonate 4% ; Stone powder 4%

......

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :