After years' of exploration and research, Richi has developed unique pelleting, conditioning and maturation technology of aquatic animals such as sinking fish and floating fish.We know very well that enhancing fish feed means enhancing the final product.

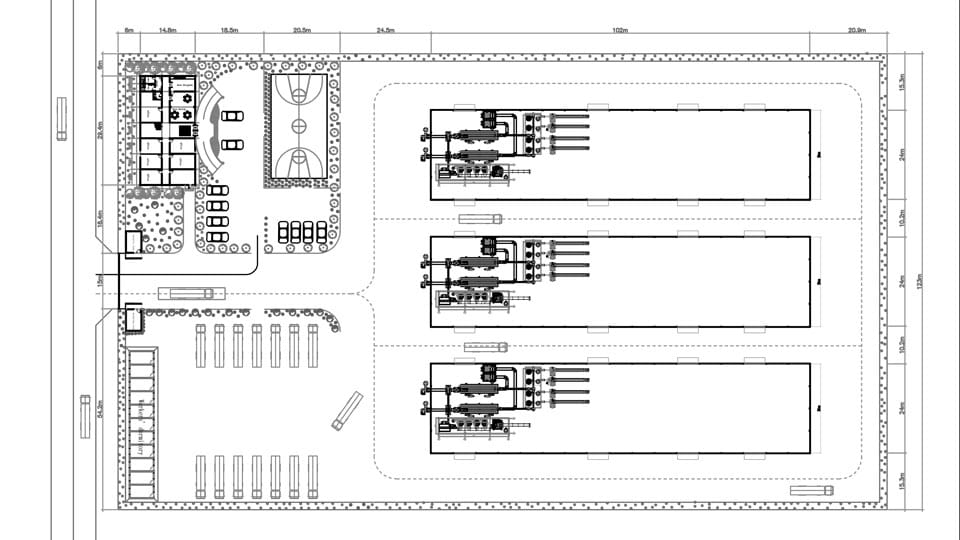

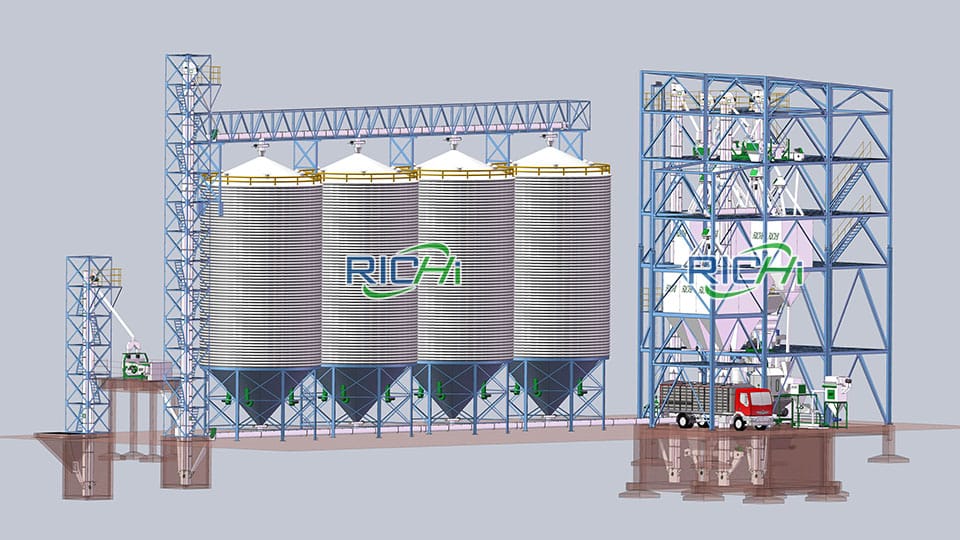

Our solutions come in a modular design so you can customize them to match your production process. At RICHI we focus on solutions that pay off, whether it's supplying the smallest spare part or serving as a long term partner. Complete Fish Feed Pellet Production Line includes the following equipments, from the storage of raw materials to the packaging of the final pellets. Each section has professional equipment to work. Of course, according to the different needs, it may be the particularity of the raw materials or the limitations of the site. Our engineers will redesign the process, and the equipment used will be increased or decreased. Click each module below, you will see the specific equipment information.

1

The raw materials used by sinking fish feed plants generally come in two forms: one is powder, it can directly enter the cone cleaning sieve to remove impurities to participate in the first batching;The other is the material that needs to be coarsely crushed ---granular materials. For individual raw materials, such as shrimp shells, etc., they can directly enter the to-be-crushed bin after magnetic separation without going through the initial cleaning sieve.

2

Primary coarse crushing is the pretreatment process of ultra-fine crushing in aquatic feed processing. The main purpose is to reduce the particle size difference and variation range of the material, improve the working condition of the ultra-fine pulverizer, improve the working efficiency of the ultra-fine crusher, and ensure the stable quality.

3

This dosing system is designed according to different feed formula, is accurate weighing process of different raw materials by using specific device. The mixing system is mixing various materials under the action of external force, after various materials are metered. It is an operation that makes the raw materials distribute evenly.After the dosing and weighing process are finished, the raw materials enter the mixer for mixing, and finally the raw materials are output by conveyor and elevator.

4

Due to the low food intake of aquatic animals, short digestive tract, and poor digestive capacity, it is required that the aquatic feed be finely crushed, and a secondary crushing process must be used. In the secondary crushing process, the primary mixed materials are lifted into the to-be-crushed bins, and then into the secondary crusher. After the secondary crushing process is completed, they enter the rotary classification screen to remove the tiny fluff in coarse fibers formed in the feed during crushing.

5

Each raw material enters the secondary mixer after secondary ingredients. An artificial feeding port is provided above the secondary mixer for the addition of trace additives, and two liquid addition devices are provided on the mixer for the addition of grease and water, respectively. In the second mixing process, all materials must be fully mixed, the coefficient of variation CV is less than 7%.

6

The design of pelleting/extruding process and the selection of related equipment are important factors that affect the quality of aquatic feed. At present, the main equipment used for this section is aquatic feed pellet mill,or fish extruder.In the extruding process, the materials are cooked under high temperature, high humidity, and high pressure for a period of time, and starch gelatinization and protein denaturation occur. The water in the feed is converted from liquid to gaseous state, and is emitted from the feed to cause the material to expand, thereby forming extruded pellet feed.With strong conditioning and appropriate feed formula, the requirements of this stage can also be achieved by using fish feed pellet mill machine.

7

After extruding or pelleting, the wet and soft pellets (moisture in 25% ~ 30%) are formed. In order to reduce the pellet breakage, it is advisable to use pneumatic conveying to dry the material from the extruder through the flow tube to the dryer, so as to reduce the moisture of the material to about 13%.

8

The screen section is mainly to screen the feed of the required pellet size. The selection of the screen can be determined according to needs. The rubber ball in the screen is best to use products with good elasticity and wear resistance, in order to improve its screening ability and service life.

9

After the material is dried, it enters the coating system. The feed coats the surface of the pellet feed with grease, vitamins, flavoring agents, etc., which not only meets the energy requirements of fish, but also reduces the loss of heat-sensitive substances during processing. And it can improve the palatability of the feed and reduce the powder content.

10

After granulation, the hot pellets are post-cured and enter the cooler to cool. Because aquatic pellet feed has high requirements on water resistance, the cooling rate should not be too fast to avoid cracks on the pellet surface. The cooling equipment used more by feed manufacturers is the counter-flow cooler, which has a good cooling effect.

11

According to the weighing in the packaging operation, the automation degree of the filling and packaging, it can be divided into three types: manual bagging, semi-automatic bagging and fully automatic bagging. The selection of the bagging type can be determined according to the customers’requirements, the size of the feed mill plant and the size of the investment.

RICHI can provide the complete turnkey project feed pellet production line, from design to install . Whether you want to produce chicken feed, cow feed or pig feed, the capacity is 1-100TPH can be choose. The main machine is feed hammer mill, feed mixer, feed pellet machine , cooling machine ,rotary sereener and others . Looking forward to your consultation !

Name: The

10T/H Automatic Chicken Feed Pellet Line

Country: Uzbekistan

Pellet Size:2-4mm

Main Material: Corn, wheat, Soybean Meal, and other Grain

Total Power:358KW

Main Machines: 1.Feed Hammer Mill*110kw;2. Batching Scale *1000kg/batch 3.Feed

Mixer*1000kg/batch ;4.Chicken Feed Pellet Machine*110KW;5.Cooling Machine*SKLN20*20;

6.Crumbler Machine*SSLG15*150 ;7. Vibrating Sereen ;8. Packing System and other auxiliary

equipment.

The field trial operation proves that the actual measured output of RICHI's 10t chicken feed pellet line is up to 13 tons, the operating current only accounts for 85% of the rated current of the motor, and each ton of feed can be 20kW•h less than the industry average power consumption. The output is calculated on the average yield of 11t/h (the initial design capacity is 10-12 tons), set to produce 8 months a year, 30 days per month, and 10 hours per day.Compared with common chicken feed pellet line of the same grade in the industry,this line can save 288,000 kWh of electricity,one yuan per kwh can ultimately save customers 28.8 million (calculated in RMB).

Send Inquiry

Name: 10T/H

Cattle Feed Pellet Production Line

Country: South Africa

Pellet Size:1-12mm

Main Material: corn, soybean meal, 50% grass and other grain

Total Power:335KW

Main Machines: Feed Hammer Mill*110KW, Feed Mixer*1000KG/BATCH, Batching

Scale*1000KG/BATCH, Feed Pellet Machine*110KW,Pellet Cooling Machine*SKLH20*20, Crumbler

Machine*SSLG15*150, Screen Machine, Automatic Packing Machine, Coal-fired Boiler*0.7MPA,

etc.

This project is currently the most advanced ruminant feed production line in the customer's local area. The project is fully computer-controlled and replaces the customer's previous manual packaging, manual handling, manual baching, and manual operations, allowing customers to experience the efficiency, energy saving, and safety of automated feed production. At the same time, the project uses a first-class process plan, the rumination process uses the most advanced production equipment in South Africa, which greatly improves the production efficiency of customers and creates economic value for customers.

Send Inquiry

Name: 5T/H Extruded Shrimp Feed Pellet Production Line in Henan

Country: China

Pellet Size:0.6-4mm

Main Material: fishmeal,homemade fishmeal, alcohol master batch, soybean phosphatide,

soybean meal, peanut meal, etc

Total Power:235KW

Main Machines: Fish Feed Grinder, Feed Ultra-fine Pulverizer, Feed Mixing Machine,

Pellet Crumbler, Automatic Batching System, Fish Feed Extruder Machine, Feed Pellet Cooler,

Screen Machine, Automatic Packing Machine, Natural Gas Boiler, etc.

The extruded aquatic project is the largest local aquatic project of the client. Its successful operation not only brings great changes to local farmers, but also lays a stable foundation for the long-term development of RICHI. The use of differentiated process equipment for this expanded aquatic project will greatly improve feed quality and profitability; at the same time, the introduction of automation and intelligent equipment will also greatly reduce labor costs, help customers improve efficiency, and reduce feed plant operating costs . During the construction process, not only advanced technology is introduced into the local area, but also resource and energy utilization are considered, so that the project saves electricity and steam.

Send Inquiry

Fishmeal 15%

Homemade fishmeal 8%

Alcohol masterbatch 4%

Soybean phosphatide 4%

Soybean meal 20%

Peanut meal 7.4%

Shrimp flour 12.5%

......

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :