RICHI always explores the best way to achieve the same value with customers, and successfully serves thousands of customers

in more than 131 countries and regions around the world.

Such as United States, Canada,New Zealand ,UK, Germany, Poland, Austria, South Africa, Russia, Uzbekistan, Afghanistan, Indonesia, Thailand,Malaysia,Vietnam,Algeria, Argentina, Peru, etc.

RICHI stick to the service principle is: We are focusing on your future, your future is our future! Provide best customized services for each customer!

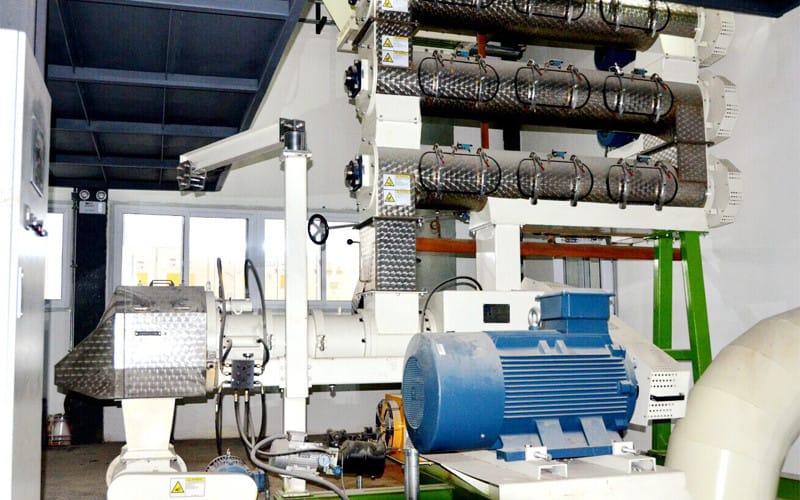

The typical advantage of this customized 2t/h wood pellet line is the simple system and compact layout, which can greatly reduce investment costs.

This biomass wood pellet plant utilizes a large amount of forestry waste and processing waste wood in the surroundings for comprehensive processing and utilization, and produces high-quality wood pellets.

Recycling used tires is not new, but the raw material for this Polish pellet project is not the tire itself, but the tire cord, does not contain rubber.

The 5t/h biomass wood pellet line project in cooperation with Austrian customers is to process 4 mm wood chip pellets, which is mainly used for heating.

Beech wood waste pellets are the biofuels that are manufactured from sawdust or similar wood residues that can be easily obtained from the different industries. Depending on the purpose of use, wood pellets are used on the commercial as well as on a perso

Germany is the birthplace of biomass pellet machines, and it is also the place where the most advanced biomass pellet machines are produced. However, on the basis of the same technology and quality, price and service have become the reason why German cust

Newly built organic fertilizer fermentation workshop 449.14m², organic fertilizer production workshop 942.24m², organic fertilizer finished product warehouse 987m³, warehouse 81.25m², manure stacking plant 525m², integrated office 172.8m².

In his 1-2 ton per hour new design biomass fuel wood pellet production line, logs and wood chips from forest harvest, offcuts and saw dust from furniture factory are used as feedstock for making wood pellets.

RICHI machinery has successfully exported a 10-15T/H fully automatic poultry feed production line and four sets of 350ton steel silo systems to Algeria. This export not only demonstrates the manufacturing strength and brand influence of RICHI Machiner

Our customer in this PET recycled plastic granules production project currently manufacture and supply recycled recycled pet resin pellets to meet the needs of the customer in a recycled solid polyester staple fiber fields in Korea and abroad. He is hopin

This 400,000 tons per year large animal feed processing plant for livestock & poultry feed is located in the southern triangle of Economic Development Zone, Hainan Province. The total investment of the project is 120 million yuan, covering an area of 40

This large animal feed making plant project is a 200,000 tons per year poultry pig fish feed production project. The site selection should meet the following requirements: it is close to its raw material supply base, the cost of raw materials and finished

In order to give full play to the company's technological advantages and provide high-quality and efficient feed products to key breeding areas in China as soon as possible, the customer invested in the establishment of a 120,000 tons per year cattle fee

The process technology used in this 8t/h pig and 8t/h dairy cow feed production factory project is relatively mature. In the entire pig production process, the equipment selected for this animal livestock feed processing plant project is carried out in a

The main construction content of the 10000t/a easy to use pig feed mill plant project mainly includes raw material warehouse, production workshop, batching room, finished product warehouse and packaging material warehouse.

The total investment of this 50000 tons per year livestock feed processing project is 4.8 million yuan, including environmental protection investment of 400,000 yuan, with a total area of 3564m2 and a total construction area of 3762m2.

In 2014, Richi Machinery had the contract for poultry animal feed pellet production with annual output 240,000 tons(Two 508 ring die poultry feed lines plus 3*1500T corn silos and 2*200T soybean meal silos) along with the contract for 5000 tons per year a

The client for this project is from Jiangsu Province, China, as the leading of domestic aquatic feed, especially special aquatic feed, mainly offers poultry feed, fish feed, protein feed, R&D of feed additives, selling and service.

Founded in 1992, with investment 80 million RMB,Customer's feed mill is located in Laishan area Yantai city. Customer's feed company is the ecological cycle agro enterprise gathering feed processing, pig and cow breeding, slaughtering, refrigeration, bi

The client of this 5-6tph cat litter pelleting project is a very well-known pet food company.The 5-6 ton/h cat litter pellet productioon project is in United Kingdom. The raw material is bentonite and attapulgite.

RICHI cat litter pellet machine can used for production 2-12mm different size cat litter. The main raw material can be choose Tofu, bentonite, waste paper, pine and others.

This project is a competitive price 10 tons per hour full automatic customized wood pellet production line. The customer's main production raw materials are some waste wood, which is relatively large and contains iron nails and other impurities.

Australia is rich in wood resources, which is very suitable for leading the entry into the wood pellet fuel market. According to Australian Pinnacle Timber Researchers, the use of wood pellets in pulverized coal power stations can play an important role i

On the basis of many previous friendly cooperation, the customers reached a new cooperation consensus with RICHI to introduce professional and efficient chicken feed mill equipments.

What he bought for the first time was a 3-5t/h powder feed and 1t/h forage feed pellet combined line, and this time he bought a 5 ton per hour sinking fish feed pellet production line for carp feed.

This is a 3-5t/h turnkey poultry chicken feed mill plant project, without any competitors, customers directly contact RICHI to discuss cooperation.

This 3-5 ton per hour broiler chicken feed pelleting line project is of great significance to Richi Machinery, because it is the first animal feed plant project established by RICHI in Uzbekistan and was signed in October 2015.

This is a customized animal feed combined line project for making 1-2 ton per hour floating fish feed and 2 ton chicken pellet feed.

This 1t/h floating fish feed and 1-2t/h cattle chicken feed pellet line project started in January 2019, the installation cycle is 60 days, covers an area of 15*9.5*8 meters,and the project is currently in production.

This project is located in Tashkent, Uzbekistan, mainly engaged in livestock and aquatic feed. It has a certain market competitiveness for local area in Uzbekistan with high quality products and services.

In May 2020, the 10t/h poultry chicken feed plant project in Fergana,Uzbekistan, undertaken by Richi Machinery, was officially completed and put into operation after installation and commissioning.

The high quality of this 10-15t/h poultry chicken feed production line is not only reflected in the exquisite design layout and installation techniques, but in the high quality and efficiency of RICHI's feed equipment.

In the face of increasing market competition, the customer from Uzbekistan planed to build a new 3-5 ton per hour poultry feed mill production line for chicken feed.

The customer of this project is mainly engaged in poultry breeding, feed processing, poultry slaughtering, and meat product processing.

For the project, RICHI is responsible for the comprehensive equipment supply and construction of complete feed production line for cattle and sheep feed. This is the decision of customer after nearly one year of research.

This customer is from Urgench and has his own chicken farm. He wants to build an easy to operate 1-2 ton per hour chicken powder feed production line for layer feed making, and all the processed feed will be used in his chicken farm.

The location of this 0.8-1.2t/h animal cattle sheep chicken fish feed processing line project is in Karsi, and the customer has not had any contact with the feed processing industry before.

In July 2020, the 1-2 ton per hour new design chicken poultry feed processing line project was successfully signed and expected to be put into operation in mid-2021.

Papua New Guinea's 1-2 ton animal feed production line is a turnkey project. From planning and model selection to project construction and trial operation, Richi is responsible.

This 1-2 ton animal feed production line constructed by Richi Machinery has a small site area and has local standards for limiting the height of the plant.

The Saudi client visited China in early 2018, visited more than ten feed machine manufacturers, and finally signed with this customized automatic feed line.

In the Afghanistan turnkey project, the core equipment and solutions are designed and provided by Richi's professional team, with reliable equipment quality and smooth process flow.

This is a turnkey project. Richi contracted all equipment installation and commissioning including civil engineering foundation.

According to the raw material and some actual needs of customers and the limited plant area, we have configured a fully automatic ingredient production line with a total power of 215KW.

On August 8, 2017, the Qatar 1-1.2 ton feed pellet production line project began, and 30 days later, the project was successfully completed.

This production line is mainly used for processing cattle feed, but it also produces sheep feed and chicken feed at the same time, so the customer is also equipped with a crumbler machine.

The raw material of this customized wood pellet making line is 50% moisture wood chips , 50% moisture sawdust, and the final size requirement is 6-12mm.

The raw material for the 10 tons of wood pellet processing project customized for the customer is wood chips, and the pellet size requirement is 8mm.

The customer of this biomass hemp pellet projct is a famer and uses the largest part of its feed production for its own poultry and livestock farms.

A fish feed extruder purchased by customers from Puerto Rico this time will be used in the 1200-1500kg/h aquatic floating fish feed mill plant.

The process of this 1t/h fish feed processing project is not complicated, mainly including grinding-dosing-extrusion/pelleting-drying--screening-packaging and other sections.

The production of 4000-5000kg for Trinia and Tobago, where the breeding industry is not developed, it is already a relatively large production.

The Colombian project customer purchased a SZLH320 poultry feed pellet mill, which will be used in a 3-4 tons per hour poultry feed processing plant.

The Brazil project customer purchased a hot sale new type wood hammer mill machine from Richi, which is the second wood pellet processing line equipment purchased from us.

The equipment purchased by Ecuadorian customers from Richi Machinery includes shrimp feed pellet making machine, 250kg/batch feed mixer and fully automatic packaging scale.

During the project, Richi strictly implements the turnkey standards. From the front-end sales manager to the back-end project delivery, every link meets high standards and high requirements.

In terms of technology, the Kenya animal feed mill line project is in line with the international animal feed engineering, and it attaches great importance to the safety and health of feed processing.

In the construction of this project, Richi undertakes the scope of workshop steel structure, warehouse steel structure, and a full set of feed equipment.

The design plan of the 10 tons per hour feed pellet project is adapted to local conditions, the entire production site layout is compact and reasonable, and the production line is smooth and simple.

The project uses a first-class process plan, the rumination process uses the most advanced production equipment in South Africa, which greatly improves the production efficiency of customers and creates economic value for customers.

Based on the current advancement of aquatic feed technology in the UK, the project customers purchased an aquatic extruded feed production line.

RICHI Machinery is in operation in key projects(evaluate before sale), the customer will receive special services from RICHI (free special coating service, on-site service, extended on-site service). These special services will allow customers to work more freely without any worries. Free technical enquire with our experts,right now!

RICHI machinery 1-80T/H different capacity full automatic pellet plant for sale the 121 countries in the world , welcome to visit our project case. As a 27years experience professional pellet equipment manufacturer, RICHI can provide the whole and one-stop pellet processing plant service for clients, solving all the feed factory construction, operation, management problems, devoting to provide modern, high-efficiency, and energy-saving feed production project construction and operation solutions for clients away from worries.

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :