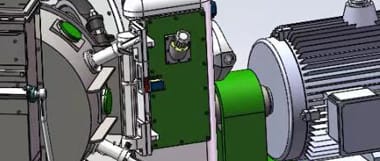

- Siemens Moror

- SKF Bearing

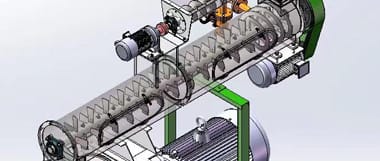

- Forced Feeder

- Conditioner

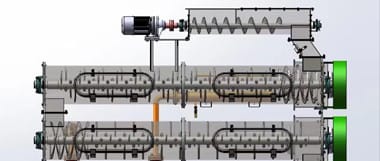

RICHI SZLH-350 Feed Granulator is based on crushed materials such as corn, soybean meal, and wheat grass, It can be used for livestock and poultry feed, especially suitable for making ruminate feed,such as cattle feed,sheep feed, camel feed, the raw material can use grain and grass, if your raw material is alfalfa and grass, this machine is the best choose.

Mode:

SZLH-350

Capacity:

5-7T/H

Main Power:

55KW

About the conditioner of feed granulator:

Paddle Model:Single-shaft paddle

Paddle Material: Stainless steel , painted 201, unpainted 304

New design: Add Forced Feeder, specially used for make grass pellet for cattle feed.

The material is transported into the conditioner through the frequency speed regulating feeder speed regulating feeder. This model adopts the advanced variable frequency motor feeding.

The Feeder and conditioner, the feeding chute adopt stainless steel material,structural durability. There are one layer conditioner, two layer conditioners, three layer conditioners , can be choosed.

The variable frequency feeding system adopts the electromagnetic valve speed control, which is convenient for speed adjustment and uniform feeding, and is fully applicable to the product requirements of different materials.

The optimized pelletizing chamber structure ensures the that the pressing material is evenly divided and maximizes the working potential of the pelletizer.

Security,has a strong magnetic magnet and overload protection device such as a safe,safe and reliable.

Compace structure,easy operation,high output,long service life, less consumption,easy to use, maintenance and quick.

RICHI Pellet machine is mainly suitable for the production of all kinds of different raw material pellets. It is mainly composed of drive system, feeding system, pelletizing system, etc. Pls cleck the every part to understand RICHI pellet machine.

1

The material is transported into the feeder through the frequency speed regulating feeder speed regulating feeder.

This model adopts the advanced variable frequency motor feeding,with overload protection devices and machines outside the nesting organization;

Stainless steel feeder of feed pellet machine:

A.belong

to

Inverter

feeder

(can

change

the

feeding

speed)

B.Stainless

steel

material

C.Siemens

electric

motor

2

Ring die type pellet machine is with conditioner. The conditioner is made by totally 100% stainless steel.

The function of conditioner :It will be connected with boiler, the steam will be supply by the steam boiler.raw materials of feed and steam will be mixed in the conditioner.

The aim of the hot steam when mixed with the raw materials in the conditioner:

The function of boiler:

(1): Hot

steam

will

kill all

bacteria

in raw

materials,

to make

the feed

more

healthy

(2):

Hot

steam

will

cook the

materials,

to make

the

final

feed

more

easily

digestiable

(3):

Hot

steam

will

make the

materials

more

soft, to

make the

materials

more

easily

to be

pressed

into

pellets.

Increase

the

final

pellet

shaping

amount

so

increase

the

production

capacity.

(4):

Hot team

will add

2%

moisture

into

materials,

the

capacity

will

increase

about

5%-10%

than

without

boiler

(5):

Hot

steam

will

cook the

materials,

make the

feed

more

delicious,

animal

will

prefer

to eat.

The fuel

of

boiler:

can be

Oil,

gas,

biomass,

coal,

electricity

etc.

3

The paddle will mix the raw material of feed with hot steam(produced from boiler).

RICHI MACHINERY’S paddles are Forged, cut directly from steel plates, more wear-resistant; many supplier ‘s paddles on their pellet machine in the market are belong to cast, not strong and durable;

The arrangement of paddles, arranged at a certain angle, and fed at a uniform speed, to ensure the full mixing of materials and steam . Improve the effect of tempering/conditioning.

Paddle Model:Single-shaft paddle

Paddle Material: Stainless steel , painted 201, unpainted 304

Paddle Types: There are one layer conditioner, two layer conditioners, three layer conditioners , three types pellet machine, we will suggest based on different ‘s customer final aimed kinds of pellet.

4

Siemens is one of the world's largest electrical and electronics companies, Siemens electric motors are synonymous with quality, innovation and the highest efficiency.

The high

efficiency

level

reduces

energy

consumption

and

directly

saves

costs

for

users.

High

protection

level to

ensure

the

safety

and

reliability

for

users.

For RICHI , the higher production costs are used to ensure better product quality. And can ensure the service life of the feed pellet machine and more stable operation.

The Power

of

Feeder:

0.75KW

The

Power of

Conditioner:1.5KW

The

Power of

Main

Machine:22KW

The

Voltage:

220v/

380v/415v

, 50hz

or 60hz,

3phase ,

can be

choosed

Imported hig-quality spindle bearings SKF bearings.

5

Pelletmachine is the key equipment in poultry and animal feed pellet producing process.

The ring die mould is the heart part of pellet mill machine, and it's one the most easy wearing spare parts as well.

This model is available in a variety of aperture between Φ1.5-Φ12 ring mold,the user can arbitrarily chosen according to different needs,in order to obtain the best technical and economic benefits;

RICHI Ring die of feed pellet machine used the 40CrMnTi, the carburizing heat treatment can improve abrasive resistance of ring die, the stainless steel doesn’t corrode easily.

About the final feed pellet size of feed pellet machine.

1.Starter/Middle Chicken , 1.5-3mm, suitable for chicken 10 10-30days

2.Big Chicken . 3.5-4.0mm, suitable for chicken in 30-45days

3.Layers Powder feeds also can feed small baby chicks

4.Cattle/Goat 5.0-8.0mm without grass in recipe

5.Cattle/Goat 5.0-8.0mm with grass in recipe

6

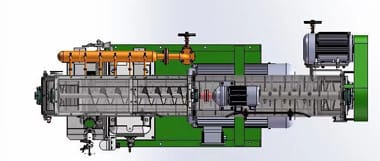

Imported gear box, high processing accuracy, high transmission efficiency, low energy consumption.

This model of feed pellet machine uses one-motor straight gear drive system,with the ideal gear ratio,drive torque, stable transmission, high output, low noise, easy operation and maintenance;

RICHI gearbox of feed pellet machine include the spindle, empty shaft, toothed shaft, 5 set SKF bearings, large gear, safety pin assembly. In addition, RICHI feed pellet machine is equipped with the door opening and power-off protection device, the cylinder cover , Coupling protection cover, Safety pin protection cover ,etc. RICHI will do our best to protect the safety of equipment and personnel.

7

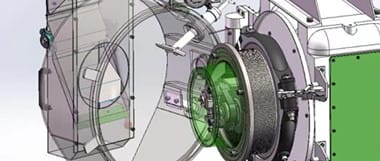

RICHI pelletizing chamber of feed pellet machine used for pelletizing feed pellet , RICHI optimized structure of the granulating chamber ensures the uniformity of the material and maximizes the working potential of the granulating machine.

The pelletizing chamber include the roller assembly, stainless steel ring die, cutter assembly, feed chute,Manuel feed inlet, etc.

The roller assembly - Made of 40CrMnTi, the structure of the eccentric shaft can better adjust the distance between the ring die and press roller.

The ring die - 304 stainless steel , corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology.

The cutter assembly can control the length of final pellet and the scraper can clean up the reduce of the empty shaft, avoid material deterioration and contamination of other materials.

8

There is a separate electric control cabinet beside each RICHI feed pellet machine, this control cabinet can independently control the operation of the pellet machine and issue instruction. In case of emergency, the pellet machine can be shut down separately for maintenance without affecting the normal operation of other equipment.

The advantages of feed pellet:

(1)the heat generated in conditioning and pelleting make the feedstuffs more digestible by breaking down the starches,

(2)Kill salmonella in feed,can protect the animal growth ,and get the high rate of return by selling pellet feed.

(3)The pelleting minimizes waste during the eating process. Aviod animal picky eaters. When pelleted feed is fed, each animal receives a well-balanced diet by preventing the animal from picking and choosing between ingredients.

(4)Easy storage and transportation,Liquidity is good,easy to manage, Feed conversion will be improved.

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :

en

en