- Simple Operation

- High Efficiency

- Wde Production Range

- Good Quality

RICHI SZLH-768 Fish Feed Pellet Machine can be used for aquatic feed, shrimp feed, fish feed. It is widely used in Individual farmers and small and medium-sized fish farms, fish poultry farms, or large, medium and small fish feed processing plants.

Mode:

SZLH-768

Capacity:

25-40 T/H

Main Power:

280/315 KW

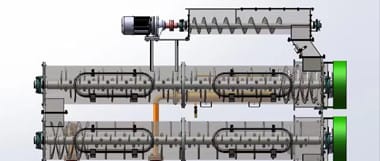

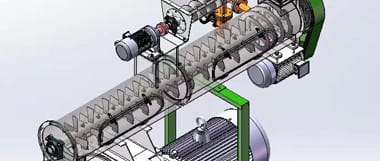

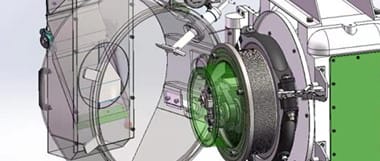

The Fish Feed Pellet Machine include the three-layer conditioner, usually suitable production the aquatic feed, fish feed, shrimp feed . The Novel multi-pass functional conditioner for long retention time. It consists of pre-confitioner for mixing material and steam intensively , keeper for long time heat preservation to promote gelatinization, breaker to futuer unify feed mash structure, and the last-pass conditioner to ensure consistent and uniform discharge.

The Feeder and conditioner, the feeding chute adopt stainless steel material,structural durability.

The variable frequency feeding system adopts the electromagnetic valve speed control, which is convenient for speed adjustment and uniform feeding.

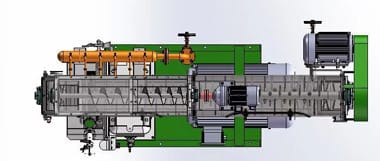

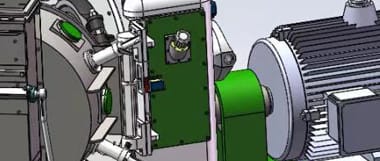

The host drive with high precision gear drive,the ring die adopt anchorear type and disassembly is convenient.

Security,has a strong magnetic magnet and overload protection device such as a safe,safe and reliable

Compace structure,easy operation,high output,long service life, less consumption,easy to use, maintenance and quick.

The optimized pelletizing chamber structure ensures the that the pressing material is evenly divided and maximizes the working potential of the pelletizer.

About SZLH-768 Aquatic Feed Machine:

Conditioner: Three-Layer Conditioner

Capacity:25-40 t/h

With on-site electric control cabinet,oiling machine. Siemens Motor, SKF bearing.

Feature: Feeder, conditioner, ring die, door are made

by stainless steel.

Size of conditioner:Length 3100mm*Dia 768mm

Rang of Final Pellet:1.0-12mm

Ring Die Inter Diameter:768mm

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :